Search keywords:

product name, product type, model number,

test method, manufacturer, technique, application

Filter Media Tester G600

BACKStandards:

Applications:

Atmospheric aerosol measurement

Indoor air quality research

Characterization of emission source particles

Aerosol characterization for inhalers, atomizers, nebulizers for drug delivery and medical research

Product Information:

Introduction

With the lower size limit extended from 10nm to 5 nm, the WPS can now count and size aerosol particles automatically from 5nm to 10,000nm (0.005μm to 10μm) in up to 120 particle-size channels by laser light scattering, differential mobility analysis, and condensation particle counting An optional electrical ionizer is available for electrical mobility analysis without the use of a radioactive ionizer

Descriptions

The Wide-range Particle Spectrometer, or WPS™, is a new approach to aerosol measurement by combining laser light scattering, differential mobility analysis and condensation particle counting into a single, compact instrument to measure concentration and size distribution of aerosol particles from 5nm to 10,000nm (0.005μm to 10 μm) in diameter. The WPS™ combines miniaturized instrument components, advanced electronics and sophisticated computer software to form one of the most advanced and user-friendly aerosol instruments ever developed. The WPS™ is easy to setup and use. Easily transported between the laboratory and the field, it is a versatile instrument suitable both for laboratory research

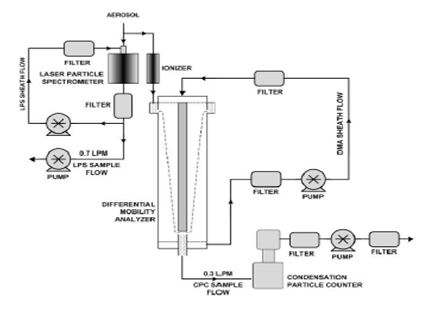

and field applications. Figure 1 is a simplified schematic diagram of the WPS™. For measurement in the 10 to 10,000 nm range, the instrument samples aerosol at the rate of 1.00 liter per minute, of which 0.7 L/min passes through a Laser Particle Spectrometer (LPS) for size analysis by laser light scattering. The remaining 0.30 L/min then passes through a differential mobility analyzer (DMA) and a condensation particle counter (CPC) to measure aerosol

particle size to a lower limit of 10 nm. Measurement to a Powerful, built-in computer. Easy-to-use software for data analysis.The Wide-range Particle Spectrometer, or WPS™, is a new approach to aerosol measurement by combining laser light scattering, differential mobility analysis and condensation particle counting into a single, compact instrument to measure concentration and size distribution of aerosol particles from 5nm to 10,000nm (0.005μm to 10 μm) in diameter.

The WPS™ combines miniaturized instrument components, advanced electronics and sophisticated computer software to form one of the most advanced and user-friendly aerosol instruments ever developed. The WPS™ is easy to setup and use. Easily transported between the laboratory and the field, it is a versatile instrument suitable both for laboratory researchand field applications. Figure 1 is a simplified schematic diagram of the WPS™. For measurement in the 10 to 10,000 nm range, the instrument samples aerosol at the rate of 1.00 liter per minute, of which 0.7 L/min passes through a Laser Particle Spectrometer (LPS) for size analysis by laser light scattering. The remaining 0.30 L/min then passes through a differential mobility analyzer (DMA) and a condensation particle counter (CPC) to measure aerosol

particle size to a lower limit of 10 nm. Measurement to a Powerful, built-in computer. Easy-to-use software for data analysis.particle size to a lower limit of 10 nm. Measurement to a Powerful, built-in computer. Easy-to-use software for data analysis.The Wide-range Particle Spectrometer, or WPS™, is a new approach to aerosol measurement by combining laser light scattering, differential mobility analysis and condensation particle counting into a single, compact instrument to measure concentration and size distribution of aerosol particles from 5nm to 10,000nm (0.005μm to 10 μm) in diameter.

The WPS™ combines miniaturized instrument components, advanced electronics and sophisticated computer software to form one of the most advanced and user-friendly aerosol instruments ever developed. The WPS™ is easy to setup and use. Easily transported between the laboratory and the field, it is a versatile instrument suitable both for laboratory researchand field applications. Figure 1 is a simplified schematic diagram of the WPS™. For measurement in the 10 to 10,000 nm range, the instrument samples aerosol at the rate of 1.00 liter per minute, of which 0.7 L/min passes through a Laser Particle Spectrometer (LPS) for size analysis by laser light scattering. The remaining 0.30 L/min then passes through a differential mobility analyzer (DMA) and a condensation particle counter (CPC) to measure aerosol

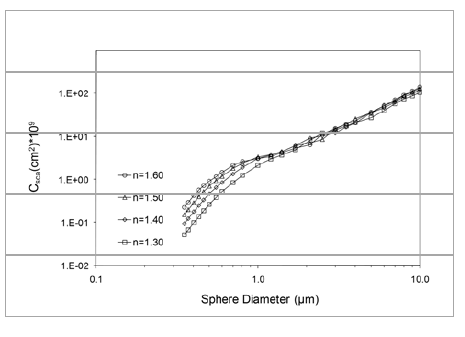

The new miniature CPC is based on a patented porous-metal saturator, dual reservoir technology of MSP. In this Dual-Reservoir CPC design, the aerosol is pre-heated before it is saturated by the working fluid (n-butyl alcohol) vapor to achieve a high degree of vapor saturation stability. The vapor saturated aerosol then flows through a condenser to activate particles as condensation nuclei for vapor condensation and droplet growth. The resulting droplets are then counted by a light scattering droplet counter. In a traditional CPC, the condensed working fluid and the condensed moisture are both returned to the working fluid reservoir. Under moderate to high humidity conditions, the condensed water would fill working fluid reservoir, thereby displacing the working fluid from the saturator pores, leading to erroneous measurement results. In MSP’s Dual-Reservoir CPC technology, the condensate is collected in a separate condensate reservoir, thereby avoiding possible erroneous concentration reading that may result from incorrect operation of the instrument under moderate to high humidity conditions. Laser Particle Spectrometer (LPS)—The LPS is a proprietary MSP design with wide angle collecting optics, a laser diode light source, and a solid state photomultiplier detector. The light scattering response of the LPS is predicted by Mie theory calculations and verified by experiments. The response function of the LPS is shown in Figure 3.

Figure 3. Light scattering response of the LPS

For refractive index between 1.30 and 1.60, the known response function of the LPS can be used to correct for sizing errors due to particle refractive index. The user can select the particle refractive index value—if it is known—for automatic refractive index correction. Alternatively, if the refractive index is unknown, the user can use the overlapping size range between the DMS and the LPS, from 350nm to 500nm (when using the DMA in the 10-500nm range), to find an empirical value for the refractive index that would minimize the count differences between the measurement techniques, thereby obtaining an estimate of the unknown particle refractive index. Calibration and Standardization—The DMA is calibrated at the factory using a NIST-traceable calibration procedure and using SRM (Standard Reference Material) 1691 from NIST, which is comprised of polystyrene latex (PSL) spheres with a NIST certified 269-nm diameter. Calibration of the LPS is similarly established using NIST spheres as well as commercial sources of PSL with NIST traceable diameters. The factory calibration of the LPS, therefore, is for a refractive index of 1.585 for the PSL. The lower particle size limit and the counting efficiency of the CPC have been established through careful comparison with other CPCs made at MSP and those available from another manufacturer. System Control—Operational control of the WPS™ is managed by a powerful single-board computer running on Windows XP OS embedded in the computer, a digital system board (DSB), an analog system board (ASB), and other custom circuit boards handling signal processing functions. For refractive index between 1.30 and 1.60, the known response function of the LPS can be used to correct for sizing errors due to particle refractive index. The user can select the particle refractive index value—if it is known—for automatic refractive index correction. Alternatively, if the refractive index is unknown, the user can use the overlapping size range between the DMS and the LPS, from 350nm to 500nm (when using the DMA in the 10-500nm range), to find an empirical value for the refractive index that would minimize the count differences between the measurement techniques, thereby obtaining an estimate of the unknown particle refractive index. Calibration and Standardization—The DMA is calibrated at the factory using a NIST-traceable calibration procedure and using SRM (Standard Reference Material) 1691 from NIST, which is comprised of polystyrene latex (PSL) spheres with a NIST certified 269-nm diameter. Calibration of the LPS is similarly established using NIST spheres as well as commercial sources of PSL with NIST traceable diameters. The factory calibration of the LPS, therefore, is for a refractive index of 1.585 for the PSL.

The lower particle size limit and the counting efficiency of the CPC have been established through careful comparison with other CPCs made at MSP and those available from another manufacturer. System Control Operational control of the WPS™ is managed by a powerful single-board computer running on Windows XP OS embedded in the computer, a digital system board (DSB), an analog system board (ASB), and other custom circuit boards handling signal processing functions.

Features

Miniature high-performance aerosol sensors and instrument components:

- High resolution Differential Mobility Analyzer (DMA) - Dual-Reservoir Condensation Particle Counter

(CPC)

- Wide-Angle Laser Particle Spectrometer (LPS)

Number of Size Channels:- High resolution Differential Mobility Analyzer (DMA) - Dual-Reservoir Condensation Particle Counter

(CPC)

- Wide-Angle Laser Particle Spectrometer (LPS)

- LPS: 24 channels

- DMS: 1 – 96 channels

- SMS: 12, 24, 48, and 96 channels - SWPS: 36, 48, 72, and 120 channels

NIST traceable particle size calibration

Pulse-width modulated control for accurate temperature and flow rate settings

Recipe control of instrument operations

Remote control and operation (wireless or Ethernet)

Five (5) user selectable modes of instrument operation

Powerful, built-in computer

Easy-to-use software for data analysis

Self-contained flow system (no external pump needed)

Configurations

Configuration A (standard)—Configuration A provides the full range of measurement capabilities of the instrument including:

Concentration and distribution measurement from 5nm – 10,000nm (no LPS-DMA overlap) or 10nm - 10,000nm (with 350-500nm LPS-DMA overlap)

Five (5) user selectable, operational modes: SWPS™ (scanning wide range particle spectrometer), WPS™, SMS™, DMS™, and LPS modes

Configuration B (optional)—Configuration B provides a more limited range of measurement capabilities including:

Concentration and size distribution measurement in two user selectable ranges: 5nm – 350nm or 10nm -500 nm

Two (2) operational modes as: DMS™ and SMS™

Configuration B can be upgraded to Configuration A at the factory by adding the LPS hardware and making associated software changes.

Technical ParametersConcentration and distribution measurement from 5nm – 10,000nm (no LPS-DMA overlap) or 10nm - 10,000nm (with 350-500nm LPS-DMA overlap)

Five (5) user selectable, operational modes: SWPS™ (scanning wide range particle spectrometer), WPS™, SMS™, DMS™, and LPS modes

Configuration B (optional)—Configuration B provides a more limited range of measurement capabilities including:

Concentration and size distribution measurement in two user selectable ranges: 5nm – 350nm or 10nm -500 nm

Two (2) operational modes as: DMS™ and SMS™

Configuration B can be upgraded to Configuration A at the factory by adding the LPS hardware and making associated software changes.

Differential Mobility Spectrometer (DMS) and Scanning Mobility Spectrometer (SMS™)

1 Sample Flow Rate 0.30 or 0.45 L/min

2 DMA Sheath Flow Rate (Recirculating) 3.0 or 4.5 L/min

3 Particle Size Range DMA, 5-350 or 10-500 nm; CPC 5 nm to 1000nm

4 DMA Sizing Accuracy Mean Mobility Diameter: ±3% referenced to 269nm NIST SRM 1691

5 CPC Count Accuracy ± 10% (compared to standard MSP CPC); <10% coincidence error;

Single particle counting mode

6 CPC Concentration Range 0 to 104 particles/cm3 (single particle counting mode)

7 CPC Coincidence 10% @ 10,000 cm-3

8 CPC Working Fluid n-butyl alcohol (butanol)

9 CPC Response Time (95% response) < 5 sec

10 DMA-CPC Aerosol Concentration Range 20 to 107 particles/cm3 (total aerosol concentration)

11 Measurement Cycle Time 60 to 300 seconds, user selectable

12 Size Resolution 12, 24, 48, or 96 channels, log scale in the SMS Mode; 1-96 channels, log or

linear scale in the DMS Mode

13 Sample Interval Time 60 sec to 24 hrs, user selectable

14 Sample Averaging 2-999 scans

Laser Particle Spectrometer (LPS)

1 Sample Flow Rate 0.7 L/min

2 Sheath Flow Rate 3.0 L/min

3 Particle Size Range 350nm to 10,000nm

4 Particle Concentration Range 0 to 500 particles per cm3

Wide-Range Particle Spectrometer (WPS™)

Wide-Range Particle Spectrometer (WPS™)1 Sample Flow Rate 1.00 L/min (or 1.15 L/min)

2 Particle Size Range 5nm to 10,000nm

3 Size Resolution User-selectable, up to 120 channels from 5nm to 10,000nm

4 Differential Mobility Analyzer (DMA) Miniature high-resolution DMA

5 Condensation Particle Counter (CPC) Continuous flow Dual-Reservoir CPC

6 Laser Particle Spectrometer (LPS) High-resolution, wide-angle LPS, 350nm to 10,000nm

7 Sample Interval Time 60 sec to 24 hrs, user selectable

8 Sample Averaging 2-999 scans

9 Instrument Modes Five (5) modes of operation

Scanning Wide-Range Particle

Spectrometer (SWPS™)

SWPS™ = SMS™ + LPS

Wide-Range Particle Spectrometer

(WPS™)

WPS™=DMS + LPS

Scanning Mobility Spectrometer (SMS™) SMS

Differential Mobility Spectromer (DMS™) DMS

Laser Particle Spectrometer (LPS) LPS

10 Ambient Pressure Range 800 to 1050 mbar absolute pressure

11 Ambient Temperature Range 10 to 35 ºC

12 Ambient Humidity Range 0-90% RH, non-condensing

13 Power 90-264 VAC, 47-67 Hz, single phase, 135 W steady state, 160 W start up

14 Dimensions 17.0” (W) x 20.5” (D) x 12.5” (H)

432 mm (W) x 521 mm (D) x 318 mm (H)

15 Weight 55 lbs (25 kg)