Search keywords:

product name, product type, model number,

test method, manufacturer, technique, application

Gelbo Flex Tester-G275

BACKStandards:

IST160.1, ISO 9073.10 , ASTM F392, YY/T 5056.6 , EN 13795-2-2004

Applications:

Experiments of disposable or reuseable surgical bedsheet, surgical clothes and clean clothes for patients clinical staff and equipments.

Product Information:

The Gelbo Flex Tester has been designed to determine the flex resistance of flexible barrier materials by applying repetitive strain. Pin hole formation is the criteria for failure and are determined by use of colored turpentine by allowing it to stain through the pin holes onto a white backing.

While the sample is being subjected to repetitive twisting and compression cycles on the Gelbo Flex Tester, air is withdrawn from the testing chamber and the particles in the air stream are counted and classified on the particle counter.

Application:

Experiments of disposable or reuseable surgical bedsheet, surgical clothes and clean clothes for patients clinical staff and equipments.

Features:

| Complies with the requirements of ISO 9073-10 and EN 13795-2 |

| For Dry State Lint Test |

| Enclosed flexing chamber (perspex box) |

| Diameter of the round plate: 82.8 mm |

| Reciprocating frequency: 60 times/minute |

| Rotating angle: 1800/time (alternating clockwise and counterclockwise) |

| Max distance of two round plates: (188±2) mm |

| Straight stroke of the dynamic plates: (120±2) mm |

| Diameter of air collector sampling end: (40±5) mm |

| Power: 220V, 60 Hz |

| Includes: |

| 1. Laser dust particle counter |

| Measured range of particle size: 0.3 gm to 25 urn |

| Eight (8) test channels: 0.3gm, 0.5gm, 0.7gm, I.Ogm, 2.0gm, 3.0gm, 5.0um, 10.0um |

| Air flow speed: (28.3±1.4) L/min |

| Sampling period: 1 to 59 minutes |

| Print function: To print counting result |

| Max collector concentration: 35,000 particles/L |

| Power: 220V, 60 Hz |

| 2. Sample template |

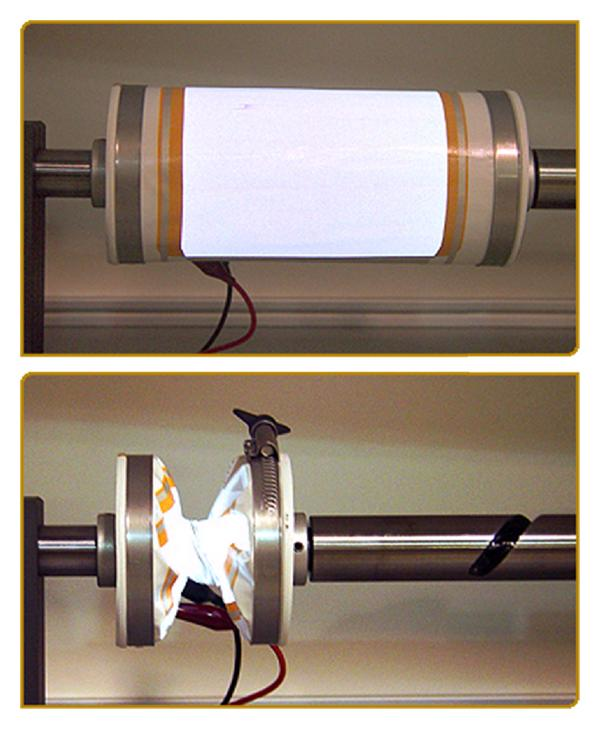

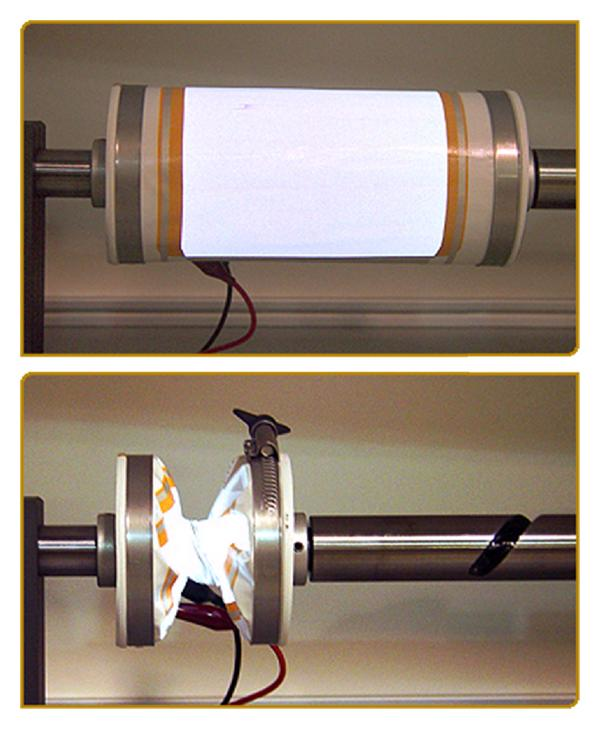

| 3. Sample roller |

| 4. Horizontal flow cabinet enclosure |

| Will accommodate the size of the gelbo flex |

| Purification class: Class 100, ISO 5 |

| Power: 220V, 60 |

Standard:

IST160.1, ISO 9073.10 ,ASTM F392,YY/T 5056.6 ,EN 13795-2-2004

Product parameters:

1, sealed torsion room and Air manual machine;

2, twist speed: 60 times / minute

3, twist angle / stroke: 180 ° / 120mm

4, sample fixture: 82.8mm

5, laser particle counter test range: collection of 0.3-25.0um samples

6, laser particle counter flow rate: 28.3L / min, ± 5%

7, sample test data storage: 3000

8, timer: 1-9999 times

Test environment:

Level 5 clean room (ie 100 clean environment)

Basic Structure:

1. Dry lint generator

1) Torsion device: to exert comprehensive force of torsion, compression and recovery

2) Torsion chamber (electrostatic resistance) : an organic glass body with electrostatic resistance which covers the torsion device

3) Air sampler: fixed on a specific location in the torsion chamber. The sample port has a certain shape.

2. Laser dust particle counter

Count and classify the particles in the sampled air.