NewsInformation Center

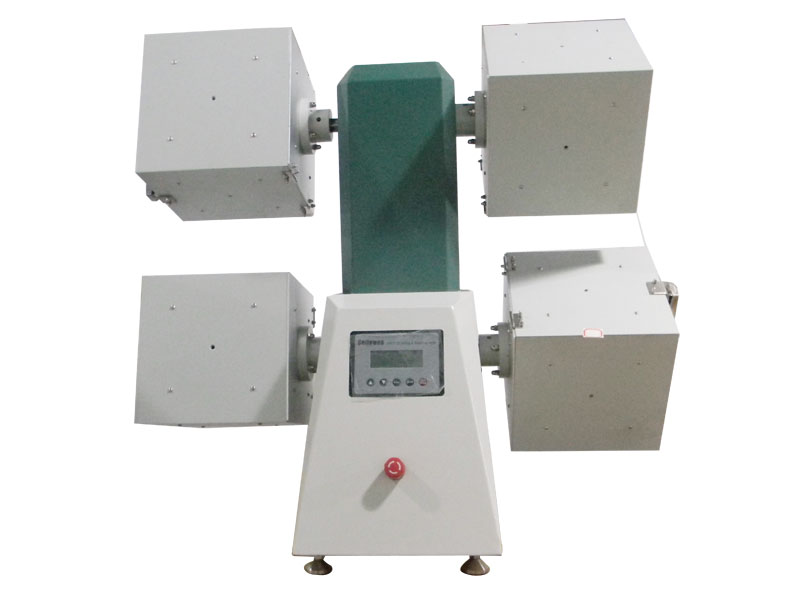

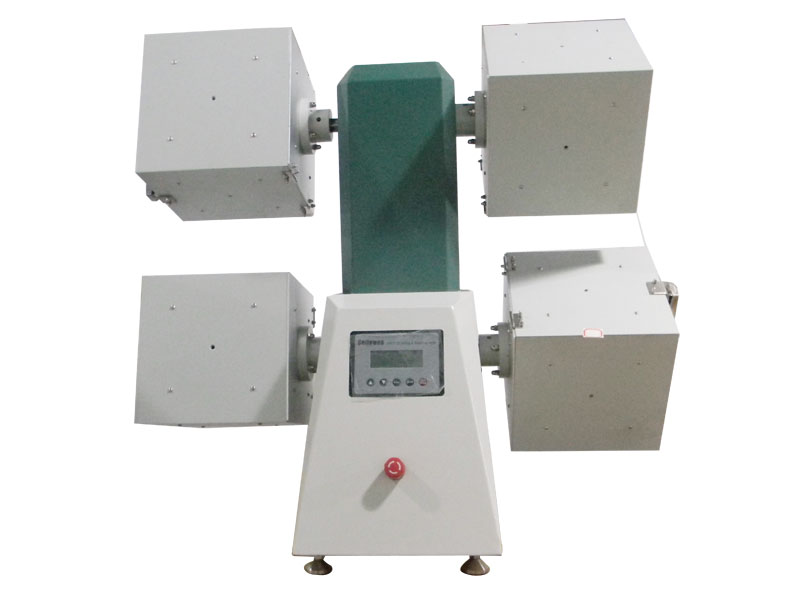

How to use the ASTM D3512 Random Tumble Pilling Tester?

2023/07/31

ASTM D3512 is a standard published by the American Society for Testing and Materials (ASTM) for testing the random pilling properties of fabrics.

The following are the general steps for using the ASTM D3512 Random Pilling Tester:

1. **Sample Preparation**: Prepare a sample of the fabric to be tested. The size and shape of the sample should meet the requirements of the ASTM D3512 standard.

2. **Instrument Setup**: Set up and calibrate the ASTM D3512 Random Pilling Tester correctly according to the equipment instructions. Ensure that the instrument is in good working condition and check if any maintenance or adjustment is required.

3. **Test conditions**: Set up the test conditions according to the requirements of the ASTM D3512 standard, including the size of the specimen, the duration of the test, and the rotational speed of the pilling tester. These conditions should be in accordance with the standard to ensure comparable test results.

4. **Installation of the sample**: Install the fabric sample in the test area of the ASTM D3512 Pilling and Snagging Tester. Usually, the sample will be fixed on the rotating disk or brush head of the test instrument.

5. **Starting the Test**: Start the ASTM D3512 Pilling and Snagging Tester and allow it to rotate and come into contact with the fabric sample according to the preset conditions. The operation of the test instrument creates friction and abrasion that simulates the conditions that fabrics experience in everyday use.

6. **Recorded Results**: Upon completion of the test, the degree of pilling and pilling on the fabric sample is examined in accordance with the requirements of the ASTM D3512 standard. It may be necessary to use specific scoring criteria for quantitative or semi-quantitative evaluation of the sample.

7. **ANALYSIS DATA**: The pilling and piling properties of the samples are analyzed and compared based on the test results and the provisions of the standard. This can help determine the durability and performance of the fabric and whether it meets specific quality requirements.

Please note that there may be other specific details and considerations contained in the ASTM D3512 standard, so it is important to read and follow the specific requirements of the standard in detail before performing the actual test. It is also important to ensure that safety regulations are followed during testing to avoid possible injuries or accidents.

Previous: 5 Important Safety Precautions for Colorfastness to Rubbing Test

N e x t : How is the rating system for textile pilling tests determined?