NewsInformation Center

What is the difference between the glow wire test and the needle flame test?

2023/08/15

The glow wire test and needle flame test are two different methods used to evaluate the flammability and fire resistance of materials. While both tests assess the ignitability and flame propagation characteristics, they differ in their test setups, application areas, and evaluation criteria. Let's delve into each test in more detail:

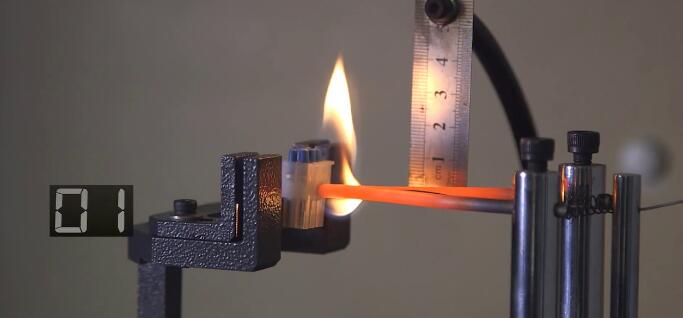

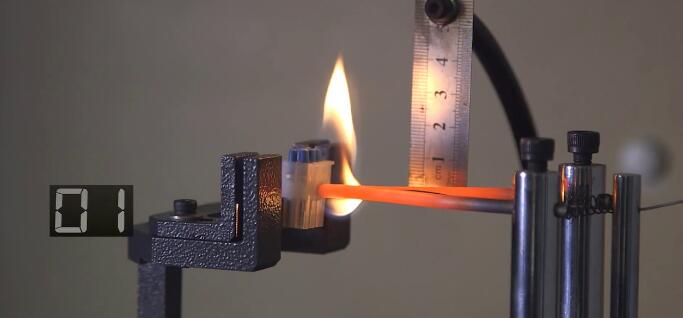

1. Glow Wire Test:

The glow wire test, also known as the IEC 60695-2-10 test, is designed to simulate the effects of thermal stresses caused by an electrical fault. It is commonly used to assess the fire hazard of electrical and electronic equipment, as well as the fire resistance of insulation materials. The key features of the glow wire test include:

Test Setup: A heated glow wire made of a specified alloy is brought into contact with the test specimen under controlled conditions. The glow wire is heated to a specific temperature (e.g., 550°C or 650°C) to simulate a high-temperature heat source.

Application: The test is particularly relevant to materials and products that are likely to come into contact with hot surfaces or excessive heat due to electrical failures, such as housing materials, wiring, switches, connectors, and sockets.

Evaluation: The test measures various parameters, including the ignition time, flammability, sustained flaming, melting, and spread of flames. The test specimen must meet specific criteria related to ignition time, afterflame time, flaming droplets, and material damage to achieve a pass result.

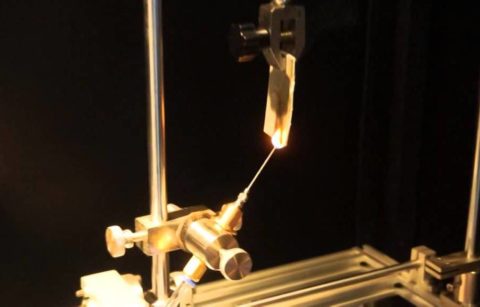

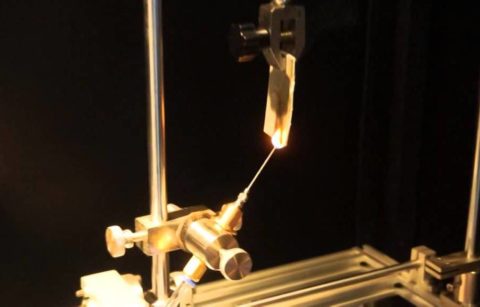

The needle flame test, also known as the IEC 60695-11-5 test or the IEC 60695-11-4 test, evaluates the resistance of materials to the ignition and spread of flames. It simulates the effects of small flames resulting from faults in devices or contact with glowing components. The main characteristics of the needle flame test include:

Test Setup: A small flame produced by a needle-shaped burner is applied to the test specimen under controlled conditions. The burner releases a precise mixture of gas (e.g., butane) and air to create a small, controlled flame.

Application: The needle flame test is commonly used to assess the flammability of materials used in a wide range of products, including electrical and electronic devices, household appliances, textiles, furniture, and automotive components.

Evaluation: The test measures various parameters, including ignition time, burning time, flame spread, and any dripping or ignition of a standard cotton pad placed below the test specimen. The pass/fail criteria in terms of flame spread and afterglow duration vary depending on the test standard and the specific product requirements.

In summary, the glow wire test assesses the heat resistance of materials subjected to electrical faults, while the needle flame test evaluates the ignitability and flame propagation characteristics of materials in the presence of a small flame. Both tests play crucial roles in ensuring the safety and fire resistance of materials and products, especially in the electrical and electronic industries. Manufacturers and designers use the results of these tests to make informed decisions about material selection, product design, and compliance with industry standards and regulations.

Previous: More information about the standard fire resistance test (ASTM E119)?

N e x t : What is the accelerated aging temperature chamber?