NewsInformation Center

What is the Erichsen scratch test method?

2023/09/08

The Erichsen Scratch Test Method (Erichsen Scratch Test Method) is a standardized test method for evaluating the surface hardness and wear resistance of metallic materials. The test method is named after German engineer Erichsen.

The Erichsen scratch test method uses a scratch tester to apply a grid of scratches to a sample at different forces. The test tool is attached to a load arm with adjustable weight, which allows the tool pressure to be adjusted to the sample. The test panel can be moved sideways so that a series of scratches can be carried out side by side with different force settings.

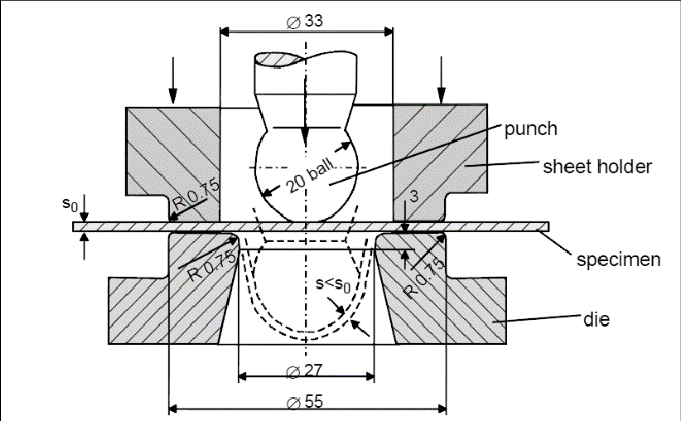

In the Erikson scratch test, a standardized metal specimen is mounted on a holder, and a spherical scratch tool is pressed against the surface of the specimen. The scratching tool is applied to the specimen with a standardized impact force and rotates to form a circular scratch. During testing, the impact force and the diameter of the scratching tool were fixed.

After the test is completed, the hardness and wear resistance of the metal material are evaluated by measuring the diameter of the scratch or the shape change of the scratch. Usually, the smaller the scratches or the less deformation, the higher the hardness and better wear resistance of the metal material.

The Erikson scratch test method is widely used for quality control of metallic materials and for comparing the hardness and wear resistance of different materials. It has applications in fields such as engineering, materials science, and manufacturing.

In what areas is the Erikson scratch test method applicable?

The Erikson scratch test method is a commonly used surface hardness testing method and is suitable for the following areas:

1. Materials Science and Engineering: The Erikson scratch test method can be used to evaluate the hardness and wear resistance of materials, such as hardness testing of metals, ceramics, plastics and other materials.

2. Manufacturing and engineering fields: During the manufacturing process, the Erikson scratch test method can be used to test the surface hardness of products, such as testing the hardness and quality of metal products, coatings, paints, etc.

3. Materials research and development: The Erikson scratch test method can be used to study the hardness properties of new materials and evaluate the wear resistance and mechanical properties of materials.

4. Surface treatment and coating fields: In the surface treatment and coating process, the Erikson scratch test method can be used to evaluate the hardness and quality of the coating, for example to evaluate the scratch resistance of the coating.

5. Quality control and quality assurance: The Erikson scratch test method can be used as a means of quality control to ensure that the surface hardness of the product meets the specified standards and requirements.

Overall, the Erikson scratch test method is suitable for use in various fields where the hardness, wear resistance and quality of materials need to be evaluated.

Previous: What is the ASTM method for scratch test?

N e x t : What is the ASTM D2863 oxygen index test?