NewsInformation Center

Which equipment is available to test the abrasion of aggregate?

2023/09/14

Testing the wear of aggregates is an important process to evaluate the hardness, wear resistance and durability of aggregates. The following are some commonly used equipment and methods used to test aggregate wear:

A wear testing machine is a device specially used to measure the wear properties of aggregates. Common wear testing machines include Los Angeles wear testing machine and Deval wear testing machine. These devices measure the wear loss of aggregates by placing them in a rotating track or drum and adding a certain amount of abrasive to cause friction and wear over a certain period of time.

2. Abrasion Disk Testing Machine:

Wear disc testing machines are used to evaluate the wear resistance of aggregates. The device consists of a rotating flat disk and some steel balls or sand. The aggregate sample is placed on a disk, which rotates at a certain speed, and steel balls or sand particles wear it. The wear resistance of aggregates is evaluated by measuring the wear amount and mass loss over a certain period of time.

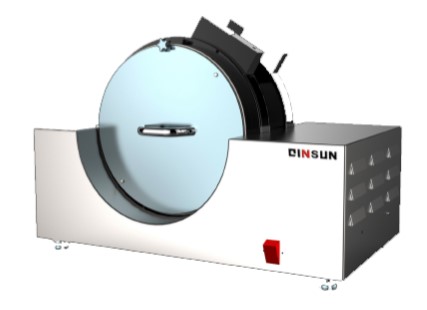

3. Coarse Grinding Wear Testing Machine:

The coarse grinding abrasion tester is used to evaluate the wear resistance of aggregates in coarse grinding abrasives. The equipment places the aggregate sample on the abrasive bed and applies a certain load to cause friction and wear on the aggregate sample through the abrasive grains. Assess the wear loss and wear behavior of aggregates.

4. Micro Abrasion Wear Testing Machine:

Microabrasive wear testing machines are used to evaluate the wear properties of aggregates at the microscopic scale. The equipment uses constant load and tiny abrasive particles to perform micro-level wear tests on aggregate samples. The wear resistance of aggregate samples is evaluated by observing and measuring the wear effect caused by abrasives on aggregate samples over a period of time.

5. Wear Testing Machine:

Wear testers are widely used to evaluate the wear properties of materials and aggregates. These devices can apply certain loads and abrasive particles through sliding, rolling or rotational motion to simulate specific wear conditions. The wear properties of materials or aggregates are evaluated by measuring parameters such as changes in wear surfaces, mass loss, size reduction, etc.

6. Slurry Erosion Testing Machine:

The suspended particle abrasion testing machine is used to evaluate the wear resistance of aggregates in liquid media. These devices simulate a liquid-solid wear environment by mixing suspended particles in a liquid medium and scouring the aggregate surface at a certain speed and load. The wear resistance of aggregate samples was evaluated by measuring the wear depth, morphology and mass loss on their surfaces.

7. Drum Wear Testing Machine:

The drum abrasion testing machine is used to evaluate the wear properties of aggregates on the drum surface. The equipment brings the aggregate sample into contact with the surface of the drum and applies a certain load to simulate the wear conditions in actual use. The wear performance of aggregates is evaluated by measuring parameters such as wear depth and mass loss.

These equipment and methods all have certain advantages and scope of application in assessing the wear of aggregates. Selecting appropriate equipment and methods for wear performance evaluation based on specific testing requirements and goals can provide valuable reference and guidance for material selection, engineering design, and product development.

Previous: What is a Hexapod test?

N e x t : What is the pull test?