NewsInformation Center

What is the ASTM standard for scratch resistance test?

2023/09/26

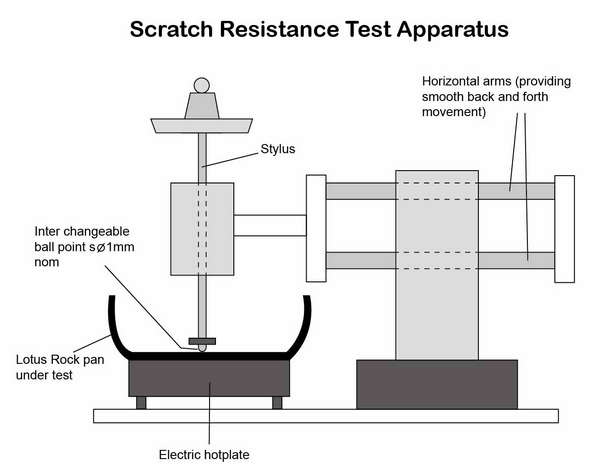

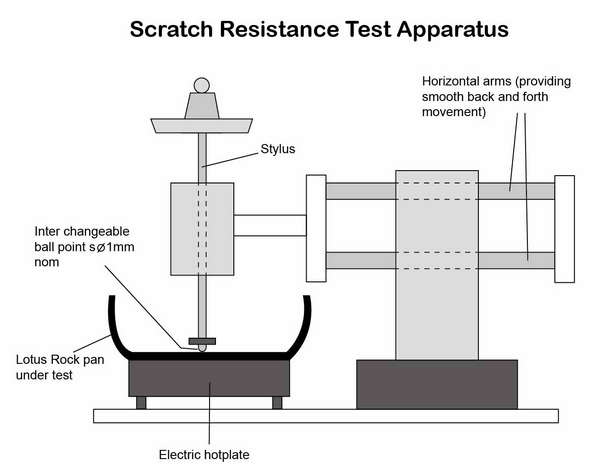

The scratch resistance test is a test method used to measure the resistance of coatings, prints, plastics and other materials to abrasion, scratches, wear and other properties of the surface. This test method simulates the degree of wear and tear on the surface of a material under actual use to determine the quality and durability of the material. scratch resistance test is used in a wide range of industrial applications, such as in automotive manufacturing, furniture manufacturing, and electronic equipment production, etc. ASTM (American Society for Testing and Materials) has developed several standards, including ASTM D4060, ASTM (American Society for Testing and Materials) has developed several standards, including ASTM D4060, ASTM D4213 and ASTM D5178, to measure the scratch resistance of materials. In this article, we will introduce the main content and testing process of ASTM D4060 standard.

The ASTM D4060 standard is one of the most commonly used standards for scratch resistance testing. It is suitable for testing a variety of materials such as plastics, paints, rubber, metals and glass. The standard is tested using a Taber abrasion tester, which utilizes a rotating circular abrasive disc to apply weight and wear loads to the surface of the material to simulate the degree of abrasion that would occur under real-world conditions.

The ASTM D4060 standard includes a variety of test methods, the most common of which is the Taber Abrasion Tester's CS-17 sandpaper abrasion head. During the test, the sample is clamped to the tester and the abrasive head is rotated and a certain load and weight is applied for a certain period of time to perform the scraping operation. After the test is completed, the degree of wear on the surface of the sample can be measured and evaluated using a scoring system specified in the standard.

The following are the main steps of the ASTM D4060 standard test:

1. Define the purpose of the test: Before conducting the test, the specific purpose of the test needs to be defined, such as determining the abrasion resistance, scratch resistance, and other properties of the material surface.

2. Prepare test samples: Prepare samples of the test material according to the standard and fix them on the testing machine according to the test requirements. Usually, samples of different materials, shapes and sizes are used for testing in order to obtain more comprehensive test results.

3. Setting up test parameters: Set up the test parameters according to the standard requirements, such as the mass and diameter of the wear head, the size of the load, the rotational speed of the wear wheel and other factors. The setting of these parameters will directly affect the accuracy and reliability of the test results.

4. Conducting the test: To start the test, the wear head begins to rotate and apply load and weight to perform a scraping operation on the sample surface. The test time varies depending on the type of material and the requirements of the test, usually ranging from a few minutes to a few hours.

5. Recording of data: The test parameters and results are recorded during the test, including the degree of abrasion on the sample surface, scores, and other indicators.

6. Data analysis and interpretation: Through the analysis and interpretation of the test data, conclusions can be drawn about the performance of the sample surface abrasion resistance and scratch resistance, providing a basis for decision-making and optimization recommendations.

ASTM D4060 standard needs to pay attention to the following points when conducting scratch resistance test:

1. the standard specifies a variety of test methods, and it is critical to select a test method that is appropriate for the particular material and purpose of the test.

2. when preparing samples, ensure that their size and shape meet the requirements of the standard, and strictly follow the standard operating procedures for testing.

3. the stability and accuracy of the working conditions of the test equipment and wear heads etc. need to be ensured during the test.

4. the test results should not be dependent on a single test, but should be averaged over a number of tests to obtain more accurate and reliable data.

5. attention needs to be paid to the safety of the test process, such as the rational use of test equipment, wearing personal protective equipment.

Many other factors need to be considered when performing scratch resistance test, such as temperature, humidity, material surface lubrication, material of the wear head and test disk, and so on. By choosing appropriate test methods and reasonable test parameters, accurate and reliable test results can be obtained and provide strong data support for product quality control and improvement.

Previous: How do you do an accelerated aging test?

N e x t : How do you perform a scratch test on minerals?