NewsInformation Center

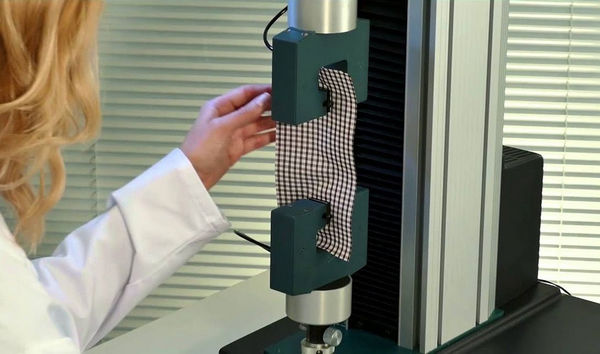

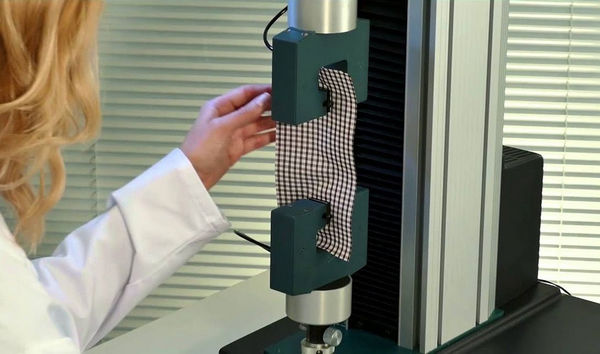

What are the testing items of a mask tensile machine?

2023/10/10

The mask tensile machine is a kind of test equipment used to test the filtration efficiency and protection performance of masks. Its main function is to simulate the use of masks under different conditions by applying certain tensile force and airflow pressure, so as to evaluate the filtration efficiency, breathability and protection performance of masks.

The testing items of mask tensile machine are more complicated, the following are the common testing items:

1. Elongation strength test:

This test usually measures the maximum strength of the mask material during the stretching process. During the test, the sample is clamped between two fixtures, the tensile force is applied at a certain speed, and the maximum stress is measured until the mask material breaks.

2. Fracture Strength Test:

This test is used to measure the ability of the mask to resist tensile fracture. In the test, a tensile force is applied to fracture the sample and the maximum stress experienced before fracture is measured. This test helps to assess the strength and reliability of the mask in actual use.

3. Elongation test:

This test is used to measure how much the mask material lengthens during stretching. During the test, the amount of deformation of the sample during stretching is measured and the elongation is calculated to assess the ductility of the material.

4. Yield strength test:

This test is used to measure the yield point of the material. In mask tensile machine, the yield strength of the material can be determined by measuring the amount of deformation and stress in the sample. Yield strength is the strength at which the material begins to deform plastically.

5. peel strength test:

This test is used to evaluate the strength of the interlayer bonding of the mask. During the test, different layers of the sample are separated and bonding strength is applied to simulate the separation of the layers. The peel strength test can help assess the quality of the interlayer bonding of the mask.

6. Extensibility test:

This test is used to assess the extensibility of the mask and its components. It involves strength and reliability testing of mask components such as nose clips, ear straps and leg bands to ensure their performance during normal use.

The above test items are common applications in mask tensile machines to assess the mechanical properties and quality of mask materials. Specific test items and criteria can be selected based on the desired test objectives and applicable standards. It is recommended to refer to the relevant standards and operating manuals, or to consult the mask tensile machine manufacturer or a professional for more detailed and specific instructions.

Previous: Is there any portable tensile testing machine?

N e x t : How does the EN 71-3 standard set limits on heavy metal content?