NewsInformation Center

Test Methods and Finishing Methods of Fabric Pilling

2023/11/15

Fabric pilling refers to the formation of small, tangled fiber balls or pills on the surface of a fabric due to friction during use or wear. There are various test methods and finishing methods available to assess and control fabric pilling. Here are some commonly used ones:

Fabric Pilling Test Methods:

1. Martindale Abrasion Test: This test is used to evaluate the abrasion resistance and pilling propensity of fabrics. It involves rubbing the fabric samples against a standard abrasive material in a controlled manner and then visually assessing the pilling formation.

2. Random Tumble Pilling Test: In this test, fabric samples are placed in a rotating drum along with abrasive elements such as cork or steel balls. The drum tumbles the samples for a specified duration, and the resulting pilling is evaluated using visual or instrumental methods.

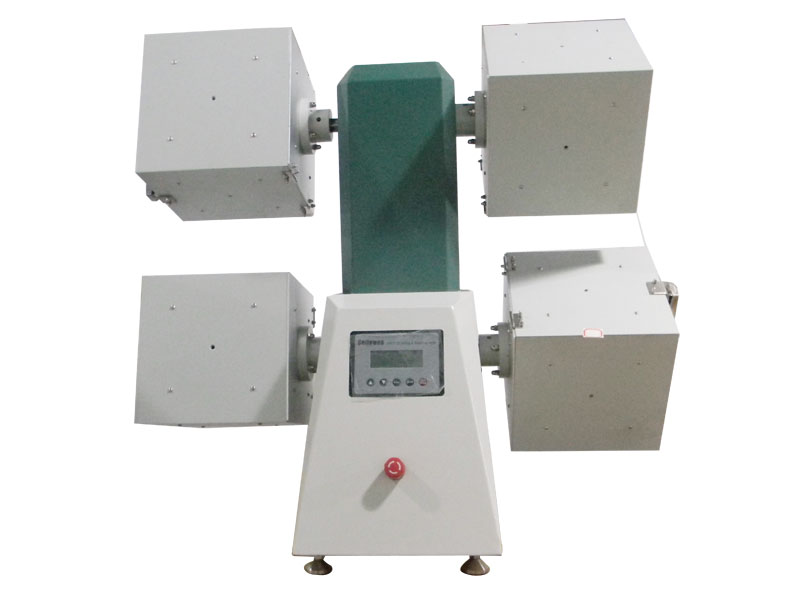

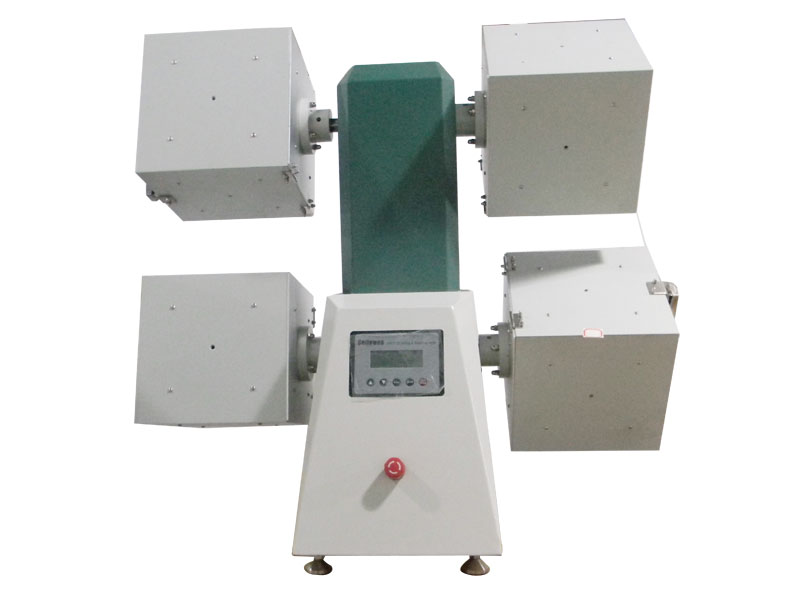

3. ICI Pilling Box Test: This test involves subjecting fabric samples to rubbing motion against a nylon brush inside a box. The samples undergo a specified number of rubbing cycles, and the pilling is evaluated using visual or instrumental methods.

4. Wyzenbeek Test: Although primarily used for assessing abrasion resistance, the Wyzenbeek test can also indicate fabric pilling propensity. It involves rubbing the fabric samples in a straight back-and-forth motion using a piece of cotton duck fabric, and pilling is assessed visually.

Finishing Methods to Control Fabric Pilling:

1. Singeing: Singeing involves quickly passing the fabric over an open flame to burn off protruding fibers or fuzz. This process reduces the surface fiber ends that can contribute to pilling.

2. Shearing: Shearing is a process where the fabric is passed over rapidly rotating blades or rollers to cut off the surface fibers or pills. This method helps to remove any formed pills and create a smoother surface.

3. Anti-Pilling Treatments: Various chemical treatments can be applied to fabrics to minimize pilling. These treatments can include the use of anti-pilling agents or resins that bond fibers together and reduce their tendency to form pills.

4. Fabric Blends: Using fabric blends with fibers that have different properties and characteristics can help reduce pilling. Combining fibers with different lengths, strengths, or frictional properties can enhance the overall fabric performance and minimize pilling.

It's important to note that the specific test methods and finishing methods used may vary depending on the industry, fabric type, and specific requirements. Manufacturers and testing laboratories often refer to relevant international standards, such as those published by ISO (International Organization for Standardization) or ASTM (American Society for Testing and Materials), for guidance on fabric pilling testing and control.

Previous: How long should a Martindale abrasion test be humidified?

N e x t : What are the main differences between tensile strength and tearing strength test