NewsInformation Center

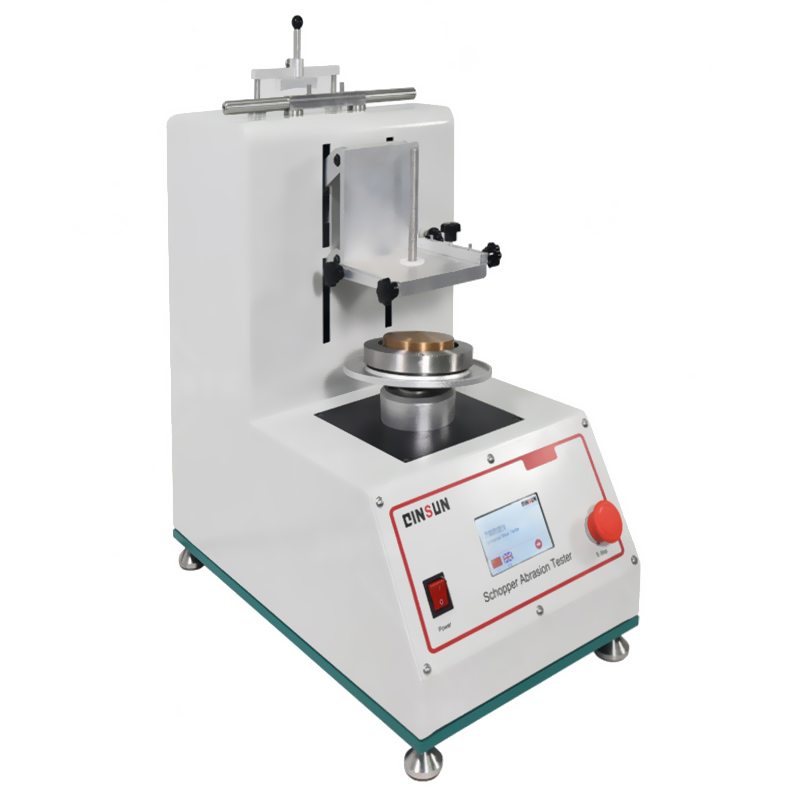

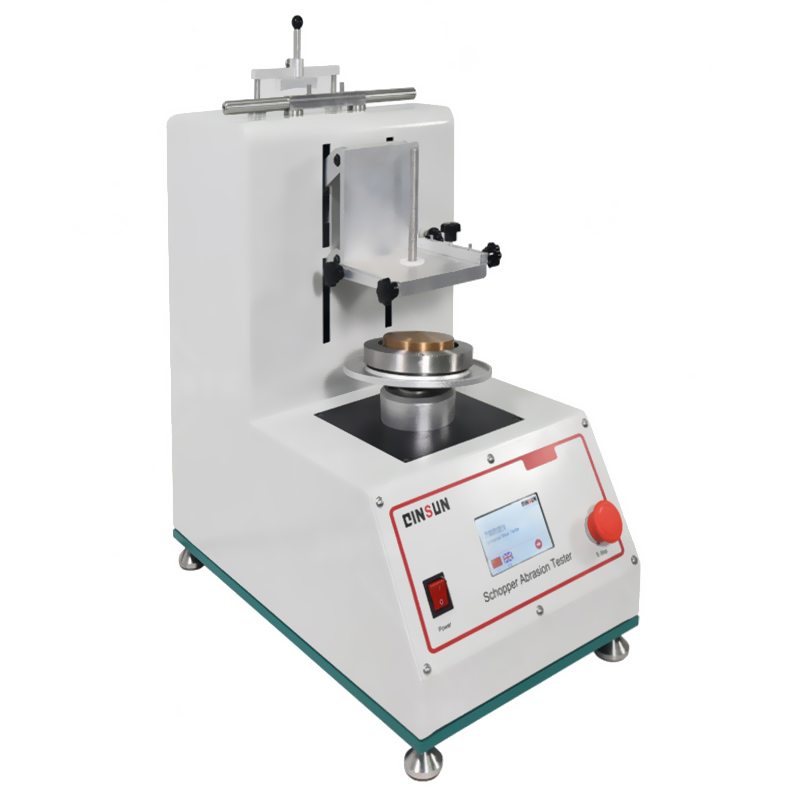

T106 Schopper Wear Tester Operation

2024/01/25

T106 Schopper Wear Tester uses a rotational wear method to test the surface changes of fabrics after friction or wear tests,and is mostly used for testing automotive interior materials.During the experiment,friction is applied to the rotating specimen in the tangential direction through friction components to determine the wear resistance of the specimen.

Compliant with standards:

DIN53863Part2"Wear resistance test(rotary wear test)on textile surfaces",GMEStandard60345,GMWStandard3283,VW/AudiPV3908

Operation:

1.Firstly,prepare the accessories and test samples;

2.Install the prepared sample into the fixture,tighten and secure it;

3.Fix the clamping device onto the loading platform equipped with a friction head;

4.From the side of the instrument,open the hidden cell and remove the weight;

5.Load the weights onto the instrument;

6.Lower the upper pressure device so that the friction head contacts the specimen;

7.Turn on the instrument switch and enter the LCD screen operation interface;

8.Set the total rotation and unidirectional rotation values;

9.Start and perform rotational friction between the sample and the friction head;

10.When the rotation set value is reached,the instrument automatically stops;

11.Remove the fixture;

12.Disassemble the fixture,remove the sample,analyze and compare it to evaluate the wear resistance of the material.

Previous: T105 Rubber Rebound Tester Operation

N e x t : T109 Multifunctional Scratch Tester Operation