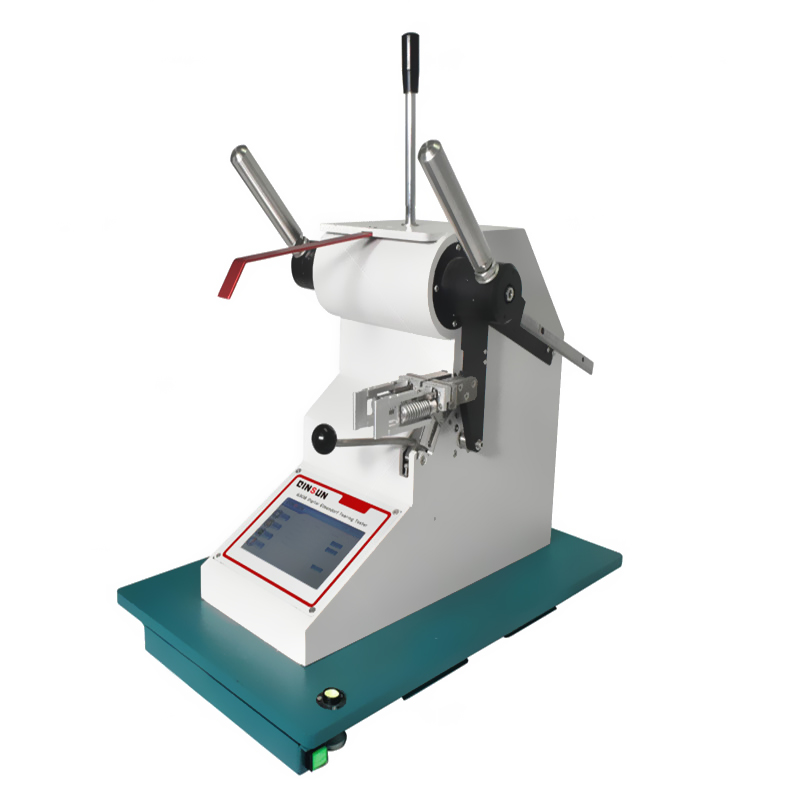

fabric pendulum tear strength tester standards and principles

2024/03/27

Testing standards:

The test method for tear strength of fabrics, GB/T 3917 specifies five methods for determining the tear strength of impact pendulum method, pants (single seam) sample, trapezoidal sample, tongue shaped sample, and wing shaped sample. This article mainly introduces the testing method of tear strength using the pendulum method.

For the testing method of fabric tear strength using the pendulum method, in addition to GB/T 3917.1, there are also ISO 13937-1 and ASTM D1424 testing standards. Among them, GB/T 3917.1 is equivalent to using the ISO 13937-1 standard. Except for ASTM D1424 which specifies two sample sizes, the other technical conditions are basically the same.

Testing principle:

The test of tear strength using the pendulum method involves cutting a section of the specimen in one direction to form two lobes, which are clamped onto the two jaws of the testing machine. When the pendulum swings and the movable fixture leaves the fixed fixture, the specimen is torn along the direction of the incision. The work done to tear a certain length of fabric is converted into tear force.

The characteristic of tearing is that the longitudinal yarn is pulled, and the transverse yarn slides. The frictional force generated by sliding is the transverse yarn being pulled. Therefore, the transverse yarn forms a force triangle area, where the deformation of the bottom edge of the yarn is greater and the external force is greater. As the distance from the * yarn increases, the force becomes smaller. When the yarn reaches the fracture elongation, fracture occurs and a peak fracture occurs, and the next yarn begins to form the bottom edge of the force triangle area. In this way, the transverse yarn gradually fractures until the fabric is torn.

Previous: fabric bursting strength tester testing principle and steps

N e x t : Fabric Breathability Tester Principles and Standards