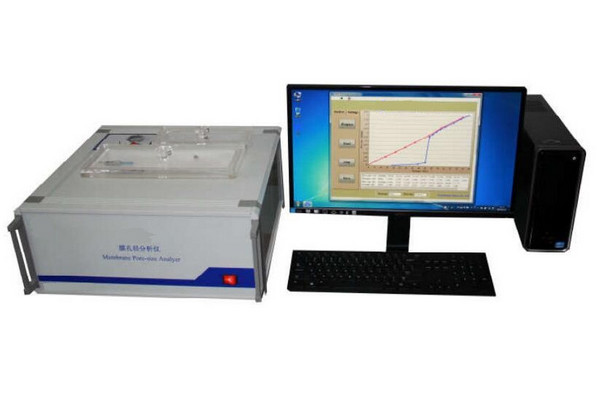

How to use GMA Ultra-filtration Membrane Porometers

2025/01/08

Applicable Standards:

ASTM F316-2003, ASTM D6767-2002, ASTM E1294-1999, ISO 4003-1990, GB/T 14041.1-2007, HY/T 051-1999, HY/T 064-2002

Usage Method:

Power-on and Preheating:

Connect the GMA Ultrafiltration Membrane Pore Meter to a power source and follow the instrument manual for power-on procedures.

Preheat the instrument to a stable state to ensure the accuracy of measurement results.

Sample Preparation:

Prepare appropriate ultrafiltration membrane samples based on measurement requirements.

Perform appropriate pretreatment on the samples, such as cleaning and drying, to eliminate the influence of surface contamination and moisture on measurement results.

Sample Installation:

Install the pretreated ultrafiltration membrane samples onto the measurement device according to the instrument manual.

Ensure good sealing between the sample and the measurement device to prevent gas or liquid leakage from affecting measurement results.

Setting Measurement Parameters:

Set appropriate measurement parameters on the instrument based on the characteristics of the ultrafiltration membrane and measurement requirements, such as measurement pressure and measurement time.

Ensure that the selected measurement parameters can accurately reflect the pore characteristics of the ultrafiltration membrane.

Starting Measurement:

Initiate the measurement program, and the instrument will automatically measure the pore characteristics.

During the measurement process, pay attention to the display and prompt information on the instrument to ensure the smooth progress of the measurement.

Data Recording and Analysis:

After the measurement is completed, the instrument will display the measurement results, including pore size, pore distribution, and porosity.

Record the measurement results and conduct necessary analysis and processing to evaluate the performance of the ultrafiltration membrane and optimize filtration processes.

Instrument Cleaning and Maintenance:

After the measurement, promptly clean the instrument and measurement device to prevent residue from affecting subsequent measurements.

Perform maintenance and upkeep according to the instrument manual to ensure the long-term stable operation of the instrument.

As a modern technology enterprise integrating R&D, manufacturing, sales, training, and services, Standard International Group (HK) Limited is committed to delivering more testing instruments to the market, providing testing instruments for textiles, leather, combustion, automotive interior and exterior trims, material environmental climate aging, etc., and non-standard customization is also acceptable. Targeted tests can be carried out according to customer requirements before purchase to ensure that the purchased instruments are applicable.

Previous: The working principle of Synthetic blood penetration tester

N e x t : Function of Medical Mask Differential Pressure Tester