Operation of Hexapod Tumbler Test Machine

2025/01/09

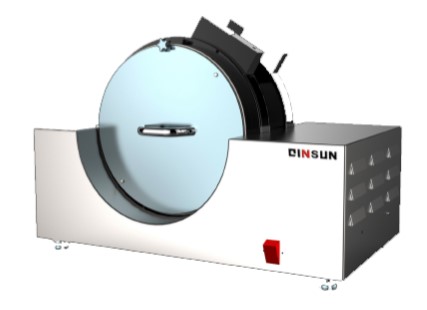

The Hexapod Tumbler test machine, also known as the Six-Legged Drum Wear Tester, Six-Legged Drum Testing Machine, or Six-Foot Drum Testing Machine, is a device used to evaluate the appearance retention and wear resistance of carpets under prolonged friction. This equipment simulates actual foot traffic by rolling over the carpet to assess its durability and appearance quality.

Standards:

BS EN 1471: 1997,ISO 9405: 2001

IWS test methods 247 & 251,ISO 10361: 2000 (BS)

Wools of New Zealand test methods 247 & 251

Technical Parameters:

Dimensions: 430mm×780mm×400mm(W×D×H)

Power Consumption: 375W

Applications:

The Six-Legged Drum Tester is widely used in carpet production, quality inspection, and research and development. During production, this tester checks whether the durability and appearance quality of carpets meet design requirements. In quality inspection, it evaluates whether carpet quality standards are met. During research and development, it provides data support for the improvement and optimization of carpet materials. Additionally, this equipment is suitable for testing all carpet products requiring appearance evaluation, observing changes in carpet surface structure and color under the mechanical action of six legs.

Operation:

Preparation Phase:

Install the sample inside the drum, ensuring the lining plate is flat and secured by the fixing groove inside the drum.

Check if the polyurethane spikes on the six legs are clean, smooth, and free of any contamination. If necessary, clean them with paper and a suitable solvent.

Starting the Test:

Connect the power supply and turn on the switch on the power socket.

Press the corresponding button to select the standard test mode, then press the run/stop button to start the test.

Testing Process:

During the test, the six-legged test blocks will roll over the carpet sample, simulating actual foot traffic and wear.

Set the drop speed (adjust the speed control knob from left to right for faster speeds). The motor drives the drum to rotate clockwise, dropping eight times per revolution.

After a certain number of revolutions (e.g., 2000 or more), the machine will sound an alarm, prompting you to remove the installed sample.

Cleaning and Evaluation:

Use a vacuum cleaner to clean the sample along its length in both directions four times, ensuring all areas are covered, with the final clean along the direction of pile tilt.

Repeat the above testing steps, usually conducting multiple tests (e.g., six times), totaling a certain number of revolutions (e.g., 12000).

After testing, turn off the tester's power and clean the workbench.

Evaluate the appearance changes of the carpet sample according to ISO reference cards or other relevant standards.

In summary, the Six-Legged Drum Tester is one of the important devices in the fields of carpet production, quality inspection, and research and development, with broad application prospects and market demand. Proper operation and maintenance can ensure the accuracy and reliability of test results.

As a modern technology enterprise integrating R&D, manufacturing, sales, training, and services, Standard International Group (HK) Limited is committed to delivering more testing instruments to the market, providing testing instruments for textiles, leather, combustion, automotive interior and exterior trims, material environmental climate aging, etc., and non-standard customization is also acceptable. Targeted tests can be carried out according to customer requirements before purchase to ensure that the purchased instruments are applicable.

Previous: Introduction of Electronic Twist Tester

N e x t : Water-cooled xenon lamp aging tester operation process inspection table