NewsInformation Center

Universal Wear Test in industrials

2019/05/10

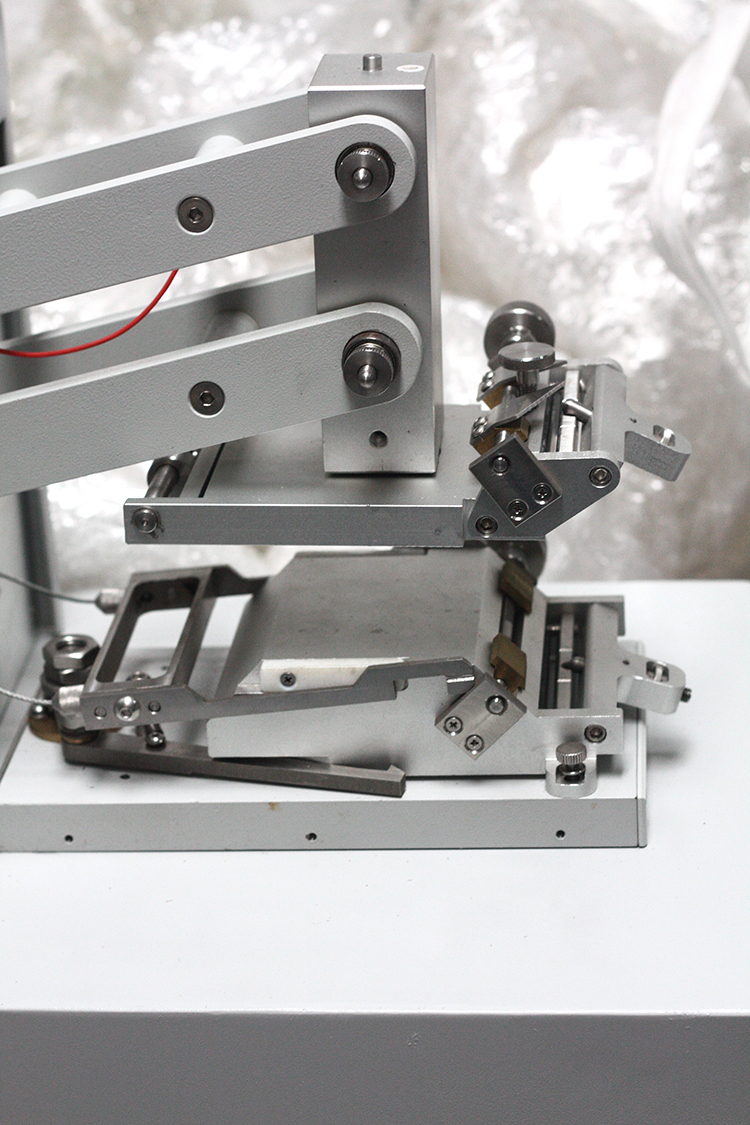

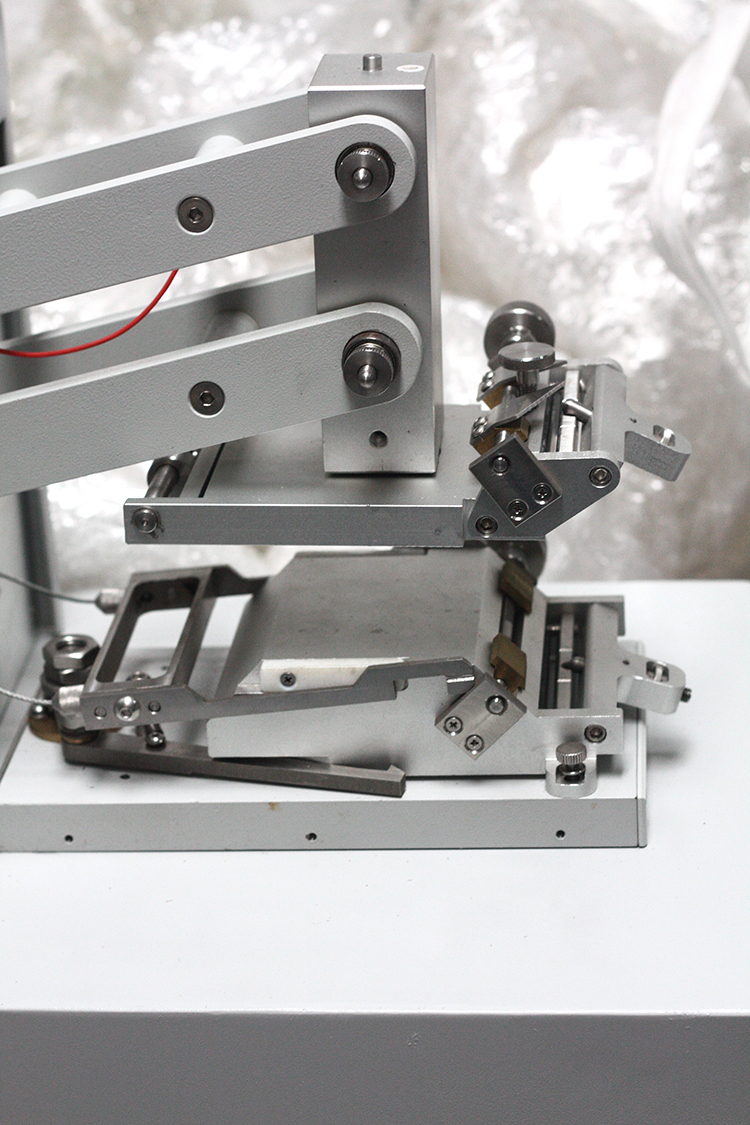

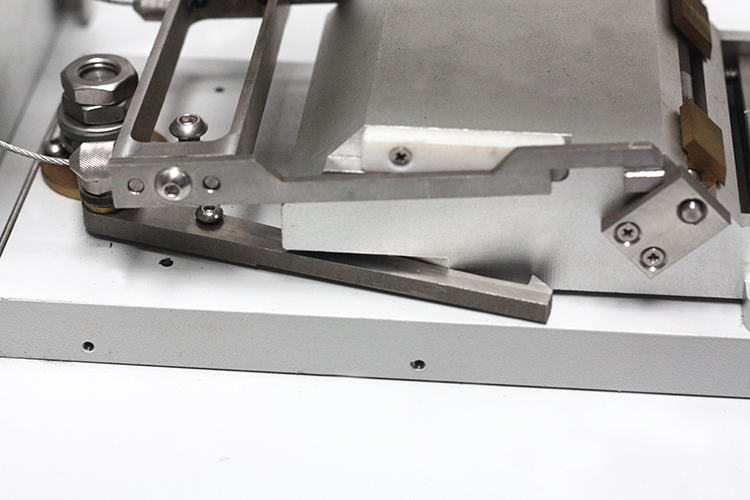

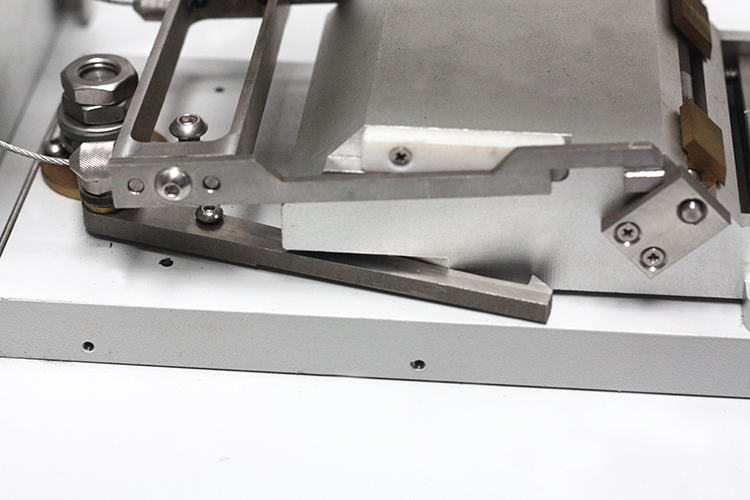

Universal Wear Tester is mainly composed of control system and friction system. The sample is installed on the clamp and is tightened. The upper fixture with the sandpaper is going down, adjust the position of the weight so that the sandpaper in contact with sample surface, through the control system set the number of friction times of the sample, and start the instrument.

Universal Wear Tester -To determines the wear and abrasion resistance of fabric used in clothing, footwear and industrials. Supplied with surface abrasion head (inflated diaphragm method, flex abrasion head, depth abrasion test device, flat abrasion (frosting) and pilling test device as well as necessary weights and initial supply of abrasive. Fitted with built-in timer and mechanical cycle counter.

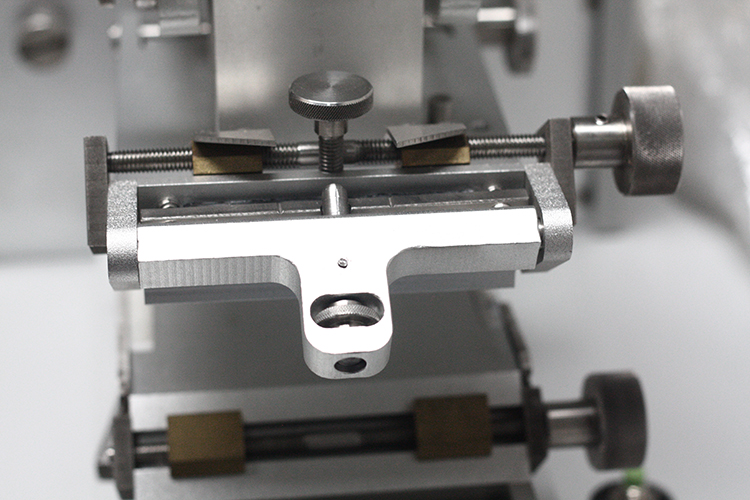

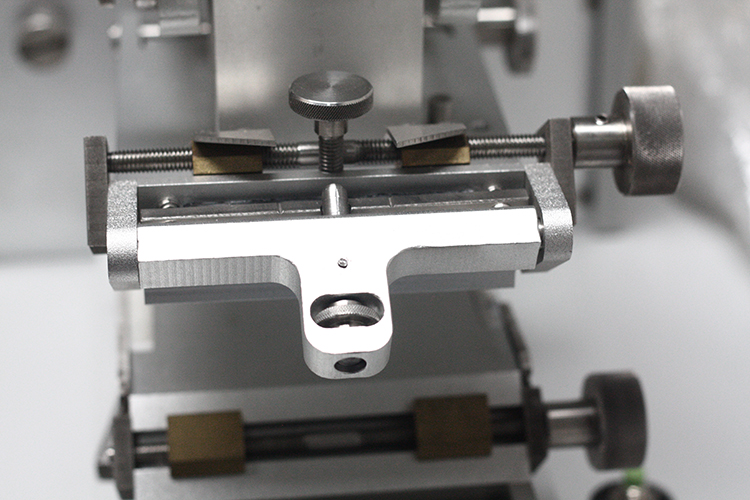

Device for install sample- for putting the sample

Flex test-to adjust test speed.

Control Panel-for machine internal ventilation

Micrometer-for deepness test (optional)

Accessories-Standard and optional accessories

Previous: The ways for inproving pilling resistance performance of fabric

N e x t : Measured Spray Rating Test Methods