NewsInformation Center

The purpose and types of fatigue testing

2019/07/11

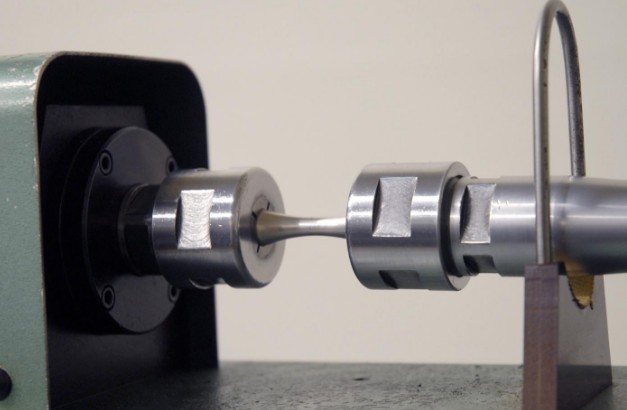

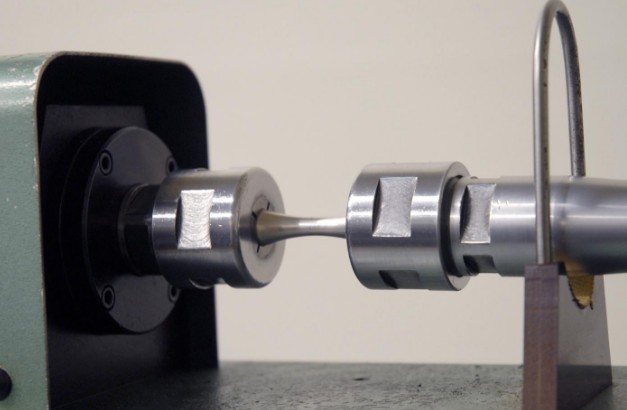

Fatigue test helps determine a material’s ability to withstand cyclic fatigue loading conditions. By design, a material is selected to meet or exceed service loads that are anticipated in fatigue testing applications. Cyclic fatigue tests produce repeated loading and unloading in tension, compression, bending, torsion or combinations of these stresses. Fatigue tests are commonly loaded in tension – tension, compression – compression and tension into compression and reverse.

A fatigue test is also used for the determination of the maximum load that a sample can withstand for a specified number of cycles. All of these characteristics are extremely important in any industry where a material is subject to fluctuating instead of constant forces.

Fatigue testing utilizes cyclic loading to predict the life of parts and raw stock under fluctuating loads. Determining fatigue life can support R&D efforts for new materials as well as prevent failures and recalls when used to ensure material properties.

Purpose of fatigue testing:

Usually the purpose of a fatigue test is to determine the lifespan that may be expected from a material subjected to cyclic loading, however fatigue strength and crack resistance are commonly sought values as well. The fatigue life of a material is the total number of cycles that a material can be subjected to under a single loading scheme.

There are several common types of fatigue testing as well as two common forms: load controlled high cycle and strain controlled low cycle fatigue. A high cycle test tends to be associated with loads in the elastic regime and low cycle fatigue tests generally involve plastic deformations.

Types of fatigue tests:

A fatigue test helps determine a material’s ability to withstand cyclic fatigue loading conditions. By design, a material is selected to meet or exceed service loads that are anticipated in fatigue testing applications. Cyclic fatigue tests produce repeated loading and unloading in tension, compression, bending, torsion or combinations of these stresses. Fatigue tests are commonly loaded in tension – tension, compression – compression and tension into compression and reverse.

Previous: Competitive Advantage Of Wear Testing

N e x t : The wear methods of high-alloy carbon steel used in mining tools