NewsInformation Center

check the fabric color fastness by running a test

2019/10/18

The color fastness test is one of the most popular, in the textile industry, during a first article inspection, production inspection or pre-shipment inspection. However, for the color fastness test on dyed yarn fabric, the process should be different. It is recommended it to be performed at an earlier stage.

We can check the color fastness of a fabric by running a test. The test methods that we usually use for Crocking/Rubbing are called "BS EN ISO 105 X12" and "AATCC 8". We need a Crockmeter to carry out this test and below is how it typically looks like.

During the test, a white conditioned rubbing cloth would be rubbing on the test specimen, back and forth in a straight line for 10 cycles with downward force. Usually, two tests would be made, one with a dry rubbing cloth and another with a wet one.

Then, after the test is done, the tested rubbing cloth should be evaluated against the grey scale under decent light source.

The color fastness to Crocking/Rubbing is categorised from 1 to 5. The higher the number, the better the fastness.

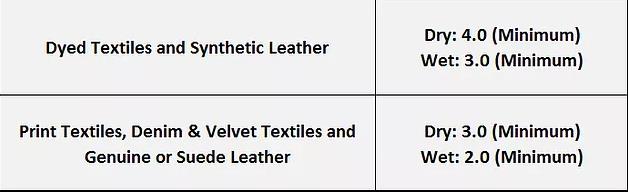

Ideally, we want no colour transfer at all. Unfortunately, it is not possible in real life. So, what should be considered acceptable? Below is the standard most companies use:

For Dyed Textiles such as Polyester and Nylon, and Synthetic Leather such as PVC and PU, the common standard is Dry: 4.0 and Wet: 3.0.

For Print Textiles, Denim, Canvas, Velvet Textiles and Genuine or Suede Leather, the common standard is Dry: 3.0 and Wet: 2.0.

Previous: Test Method For Rubber Plastic Materials

N e x t : New Direction For The Textile Market