NewsInformation Center

Influencing factors of polyurethane oxygen index determination

2021/04/29

Polyurethane (PU for short) is the abbreviation for polyurethane. It is a heat-insulating material widely used in construction and industrial equipment, and an important material in industries such as automobiles, shipbuilding, and packaging. However, due to the special structure of polyurethane foam itself, it is extremely easy to burn, and its oxygen index is only about 17%. When burning, it releases a large amount of smoke and poisonous gas, which is prone to dripping. Its flammability problem has always been an important subject of polyurethane industry research. Countries around the world have formulated various flame-retardant standards and regulations for testing polyurethane, and gradually improved the testing methods, and produced various testing instruments and equipment. The oxygen index is one of the signs to determine the flame retardant performance. In the oxygen index test, it will be affected by factors such as environmental conditions, operators, and sample preparation differences. In order to more accurately determine the oxygen index value of the material, Shanghai Qianshi Precision Electromechanical The engineers of Technology Co., Ltd. discussed the influence of various factors on the oxygen index during the test.

Reference standard:

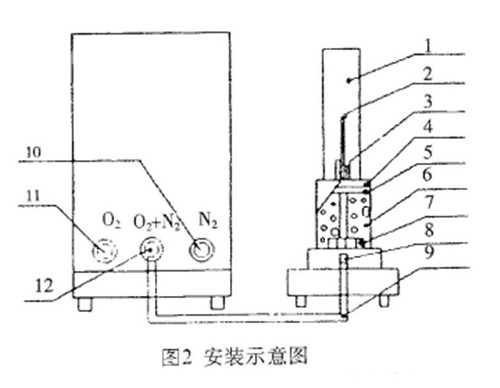

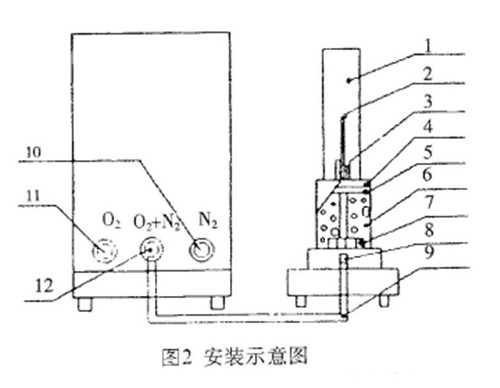

The oxygen index is in accordance with GB/T2406-1993, the standard environment for sample state adjustment and testing is in accordance with GB/T2198-1988, and the test instrument uses an oxygen index tester.

Experimental principle:

Experimental principle:

Limiting oxygen index (LOI) is abbreviated as oxygen index, which is one of the signs for judging flame retardant performance. It refers to the minimum oxygen concentration required for the sample to maintain equilibrium combustion in a mixed gas flow of oxygen and nitrogen under specified conditions. The percentage of the occupied volume is expressed.

The principle of the oxygen index method is to vertically hold a sample of a certain size in a transparent combustion cylinder with a sample holder, in which there is a flow of oxygen and nitrogen mixed in a certain proportion and flowing upward. Ignite the upper end of the sample, observe the subsequent burning phenomenon, record the continuous burning time or the burned distance, and compare it with the specified value. If the specified value is exceeded, the oxygen concentration will be reduced, and if the specified value is insufficient, the oxygen concentration will be increased. Repeat the operation from the upper and lower sides. Gradually approaching the specified value, until the concentration difference between the two is less than 0.5%.

Influencing factors of oxygen index:

Influencing factors of oxygen index:

1. The influence of state adjustment time

According to the requirements of the national standard GB/T2918-1988, the state of the test materials is adjusted to minimize the impact of environmental accidental factors on the test results. Therefore, the prepared TDCPP flame-retardant polyurethane foam sample is selected for comparison test, and the temperature and humidity of the thermostat are adjusted to a specific value required by the national standard (temperature: 23℃; relative humidity: 50%; air pressure: 86~106 kPa) .

It can be seen from the test data that as the adjustment time of the sample increases, the average value of the oxygen index obtained in the test continues to decrease. When the adjustment time meets a certain time limit, the oxygen index remains stable. The test results of the samples under different adjustment times are different. Therefore, the samples should be strictly adjusted according to the standard requirements, and then tested, in order to obtain an accurate oxygen index value under the standard state adjustment time.

2. The influence of sample ignition method

According to GB/T2406-93, two ignition methods are selected for the oxygen index test of TDCPP flame-retardant polyurethane foam samples, and the ignition time is 15s.

Top lighting method:

Make the lowest visible part of the flame contact the top of the sample and cover the entire top surface. Do not make the flame touch the edges and side surfaces of the sample.

Diffusion ignition method:

Fully lower and move the igniter so that the visible part of the flame is simultaneously applied to the top surface and the vertical side surface of the sample about 6mm long. It was found that when the same material was tested under the same conditions, the different ignition methods had little or no effect on the oxygen index measurement data, which was not enough to change the evaluation of the sample oxygen index results. Regardless of the ignition method, when to remove the ignition source and start timing is to visually judge the ignition situation of the sample with the naked eye, there is a certain error, and may cause an impact on the inspection data. Only by increasing the number of tests can we try our best Reduce the error. In actual operation, the top ignition method is more labor-saving when igniting the sample.

3. The influence of sample length

The length of the sample of the tested product in the national standard is 70-150mm. The purpose is to keep the length of the glass cylinder of the test instrument consistent, and make the oxygen concentration in the small environment mixed gas in the glass cylinder uniform and constant.

It can be seen that the length of the sample has a great influence on the inspection data. Within the range required by the national standard, the oxygen index value measured as the length of the sample increases. When the length of the sample is short, there is still a considerable distance from the top of the burning area of the tested sample to the top of the cylinder, so the oxygen required for its flame combustion is completely supported by the instrument itself and is not affected by the airflow outside the cylinder. However, as the length of the sample increases, the distance between the combustion area of the tested sample and the top of the cylinder becomes shorter, and the flow of oxygen required for flame combustion is gradually affected by the airflow outside the cylinder. In order to be able to support flame combustion, the instrument itself must provide more oxygen to satisfy the flame combustion. As a result, the measured oxygen concentration value gradually increases. Therefore, the length of the tested sample should be specified as a specific value instead of a range value to reduce the degree of influence of the indoor ambient air flow on the combustion conditions in the cylinder of the instrument.

4. The influence of flame retardants

Flame retardant is an expensive additive in polyurethane foam. Its role is very important. The amount of flame retardant is not the better, and the influence of the amount of flame retardant on the physical and mechanical properties of the foam should also be considered. In view of the consideration of cost, safety, meeting flame retardant technical indicators and foam physical and mechanical properties, it is necessary to optimize the use of appropriate flame retardants to maximize their effects.

The influence of the amount of flame retardant added:

The data shows that for TDCPP flame retardant, based on polyether polyol, 10Phr of TDCPP can make the oxygen index of PUF at 23%. The oxygen index of PUF increases with the increase of flame retardant addition, but the amount of TDCPP After more than 15Phr, if the amount of TDCPP is increased, the oxygen index of the sample will increase very limitedly.

The influence of different flame retardants:

Different flame retardants have different flame retardant effects in polyurethane foam. With the change of flame retardant content, the law of flame retardant changes is also different. This is mainly due to the difference of flame retardants and the difference between flame retardants and polyurethane foam. Influence of foam compatibility.

TDCPP is an additive flame retardant with no reactivity but flame retardant effect. With the increase of the amount of flame retardant, the flame retardant performance also increases, but when the addition amount is more than 20%, the improvement of flame retardant performance is not obvious, and the flame retardant and the combined polyether will release some Acidic substances also have a certain plasticizing effect in the foam, which will cause the foam strength to decrease. Therefore, the amount of flame retardant added is about 15%.

According to the flame-retardant mechanism, phosphorus can interact with the polymer or ambient oxygen during the combustion process to generate a series of derivatives such as phosphoric acid, metaphosphoric acid and polymetaphosphoric acid. These glassy liquid derivatives have high thermal stability and can be used in An isolation film is formed on the surface of the polymer. Its formation can not only block the heat from the flame zone to decompose the polymer, but also prevent the decomposed combustible gas from entering the flame zone. Moreover, polymer decomposition and combustible gas combustion tend to promote or weaken each other. Therefore, the formation of this liquid film covering layer will inevitably promote a substantial increase in the flame retardant effect. The flame retardant effect of melamine is mainly that it can catalyze the formation of a carbon-bonded solid covering layer. The flame retardant effect of aluminum hydroxide lies in its ability to form The solid protective layer of aluminum oxide forms a non-combustible barrier between the fire source and the foam, thereby playing a flame retardant effect. On the other hand, it contains a large amount of crystal water, which is stable during the foam production process, but it will Quickly decompose, endothermic and cool down.

For more information, please visit us at: https://www.qinsun-lab.com/index.html

Or send us email at info@qinsun-lab.comFor more information, please visit us at: https://www.qinsun-lab.com/index.html

Previous: Evaluation and testing of safety standards for automotive interior materials

N e x t : Instrument operation steps of automobile sealing strip wear tester