NewsInformation Center

What are the tests that must be done on the interior parts of the car?

2022/07/19

Cars are gradually becoming the necessary transportation for people to travel. As the awareness of environmental protection and safety of auto products increases, people are paying more and more attention to the interior materials when selecting cars. As we all know, a safe and qualified car needs to meet the ELV, VOC and other harmful substances testing. It is not known that the car interior parts also need to meet the following requirements to ensure the environmental safety of the car interior environment.

What are the tests that must be done on the interior parts of the car?

1、Flame retardant performance

Combustion safety performance is an important indicator of automotive interior materials. Automotive interior materials, especially textiles, must have good flame retardancy and fire retardancy. So that once the car fire danger can ensure that passengers have enough time to leave, or reduce the risk of fire.

Ordinary automotive textile materials may be used to a variety of fibers, because their composition and chemical structure are different, so their thermal and combustion properties are not the same. The current standard used for flame retardant performance testing is GB 8410-2006 "Combustion Characteristics of Automotive Interior Materials", which is applicable to all automotive interior materials. Common evaluation methods are: vertical combustion test, horizontal combustion test, 45° angle combustion test.

2、Atomization performance

Before the use of automotive interior materials will go through a variety of functional finishing, in the installation process will generally use adhesives, so the finished automotive interior materials may contain many low-molecular volatile substances, these volatile substances in the heat will evaporate and condense on the window glass and windshield, forming a "fog" on its surface. "phenomenon. Window glass "fog" is difficult to remove, so it will seriously affect the driver's vision, and suspended in the air volatiles may be inhaled by the human body, which will affect people's health and safety. Therefore, the car interior fabric must have a certain anti-fogging performance.

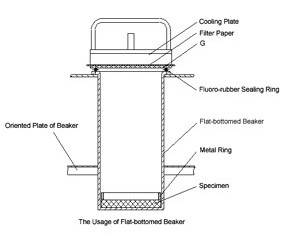

At present, the test for automotive parts fogging performance, the international use of ISO6452 "rubber, plastic, artificial leather - automotive interior parts fogging characteristics of the determination", the main domestic use of QB / T "leather physical and mechanical test fogging properties of the determination".

3、UV resistance performance (light aging test)

At present, the car in order to meet the requirements of light and car lightweight, the window glass will occupy a large area, with the sun rises, in some extreme climatic conditions, the internal temperature of the car can reach 130 ℃; with the sun's descent, the temperature inside the car and down, which will greatly affect the relative humidity of the car. Such a large hot and cold cycle may accelerate the aging of non-metallic materials, not only affect the service life of the material, and textile fading will greatly affect the fabric aesthetics. Therefore, automotive interior materials are required to have good light resistance and UV resistance. Auto interior materials often do light aging test: xenon arc lamp aging test, carbon arc lamp aging test, simulated ultraviolet light aging test.

The above is a dry sharing of the test of automotive interior parts, welcome customers who have the intention to buy to order!

Previous: Textile color fastness testing notes

N e x t : How do I determine the test time for the Xenon Arc Weatherometer?