NewsInformation Center

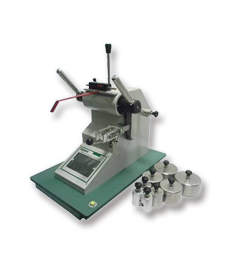

Digital Elmendorf Tearing Tester for Medical Protective Clothing

2022/12/15

Pendulum tearing strength tester is suitable for impact pendulum method (Elmendorfmethod) to determine the tearing strength of fabric or clothing fabrics, can also be used for protective clothing tearing strength performance test, is our standard group (Hong Kong) Limited independent research and development production of experimental equipment, heavy hammer: A-800g, B-1600g, C-3200g, D-6400g.

Testing principle.

Specimen fixed in the clamp, the specimen cut a cut, release the pendulum in the position of resistance potential energy, movable clamp leaves the fixed clamp, the specimen is torn along the direction of the cut, the work done to tear the fabric a certain length is the tearing force.

Applicable standards.

GB/T3917.1 fabric tearing performance part 1 tearing strength determination of impact pendulum method

ISO13937.1 fabric tearing performance part 1 with the impact pendulum method for the determination of tearing strength

ASTMD1424 Determination of tearing strength by impact pendulum method (Elmendorf)

JISL1096Section8.15.5, MethodD Pendulum method for testing the tear strength of woven fabrics

JISL1018Section8.16.1, MethodA Pendulum method for testing the tear strength of knitted fabrics.

Environmental conditioning.

1. The specimen shall be humidified and tested at a temperature of 21±1℃ and a relative humidity of 65±2%;

2. The specimen should be balanced in the above environment for at least 4 hours before the test;

3. The specimens should not be placed in layers during the commissioning.

Specimen preparation.

1. Take 5 specimens in each direction of warp (length direction) and weft (width direction), and make each test sample in the same direction does not contain the same warp and weft yarns.

2. When cutting the sample, if it is a net color cloth, the yarn at the edge of the sample should be removed, and then the sample template should be placed so that its short side is parallel to the yarn in the opposite direction to be tested. That is: if the warp yarn needs to be tested, the short side of the template should be parallel to the weft yarn; if the weft yarn is tested, it should be parallel to the warp yarn.

3. The sample should be taken at least 15cm away from the edge of the cloth, and "↑" should be used to indicate the warp direction on the cut test sample.

Previous: You must know the 9 kinds of textile testing instruments and equipment

N e x t : Medical glove chemical protection performance tester test procedure