NewsInformation Center

How to use a friction tester to test the scratch resistance of automotive interi

2023/02/22

At present, scratch resistance testing is a routine testing item for the surface quality control of automotive interior and exterior trims. For example, scratches are left on the surface of paint and plastics, causing discoloration and gloss changes, and hairs on the surface of fabrics.

Friction testing machine testing principle:

The basic principle of the five-finger scratching and friction testing machine is that the scraping head acts on the surface of the test sample with a certain pressure, and at the same time the scraping head and the test sample move relative to each other at a certain speed. The trajectory is generally a straight line (or circle), and then The scratched part of the surface of the test sample is visually inspected or measured by an instrument to determine the scratch resistance of the test sample.

Test sample preparation:

The samples for the scratch test are required to be flat. They can be specially made test specimen blocks using the same process as the product, or they can be cut from parts that are sufficiently flat.

experiment method:

1. During relative movement, the scraping head may move, but the test sample does not move;

2. The scraping head does not move, but the test sample moves;

3. In one test, some only require scratching on the test sample once, and some require repeated scratching multiple times, or scratch on different parts of the test sample to form multiple scratches.

Result evaluation rules:

Main observation: whether the appearance is scratched, whether the surface is deformed, and whether there is any change in color and gloss.

How to use the friction tester to test the scratch resistance of the interior and exterior parts of the car?

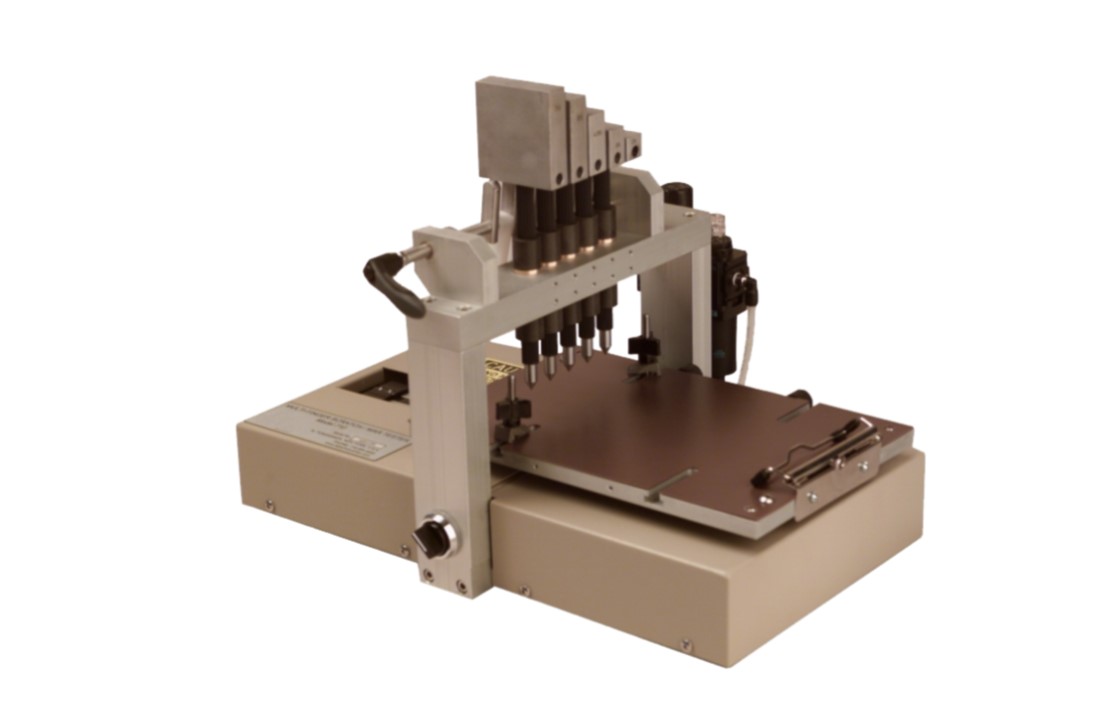

Five-finger scratch test:

The five-finger scratch tester is used, and the test sample is installed on the test bench of the instrument. Above it is the mounting frame of five scraping rods (commonly known as five fingers). The scraping rods can be easily loaded and unloaded. Various specifications, diameter 1mm or 7mm, assembled according to requirements. Loads are installed above the scraping rods, and different loads are generally installed on the five scraping rods, such as a set of 15.0N, 10.0N, 7.0N, 3.0N, 2.0N loads or a set of 20.0N, 15.0N, 13.0N, 8.0N, 5.0N loads, etc., the five scraping rods may not all be used in the test, and the scraping rods at the corresponding positions can be suspended or not installed as required. During the test, the tip of the scraping rod is placed on the test sample under the load. A surface that floats freely up and down with the surface. There are two ways for the current instrument to realize the scraping movement, one is that the scraping bar moves horizontally and the test sample does not move, and the other is that the scraping bar remains horizontal and the test sample moves horizontally. The scraping distance is generally 100~200mm, and the scraping speed is 100mm/s.

Previous: Features of M021A air permeability tester

N e x t : Salt spray test chamber spray and compressed air principle