NewsInformation Center

What is the colour fastness ISO method?

2023/05/30

The ISO method for color fastness is a standardized method for measuring the color fastness of fabrics, developed and managed by the International Organization for Standardization (ISO). This method can evaluate the color fastness of fabrics under different conditions, including resistance to water, perspiration, rubbing, washing, light, etc. Several aspects of the ISO method for color fastness are described below.

Color fastness grade

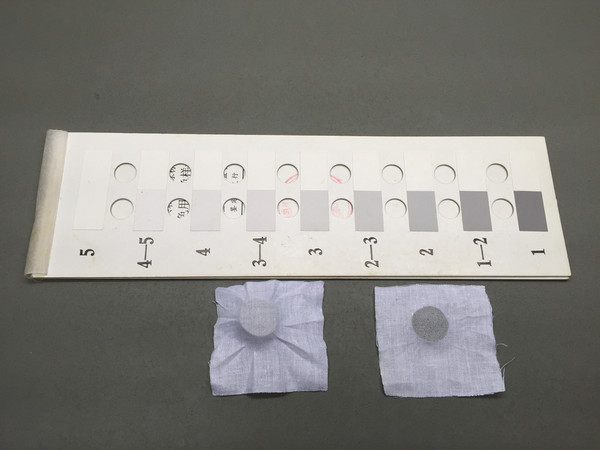

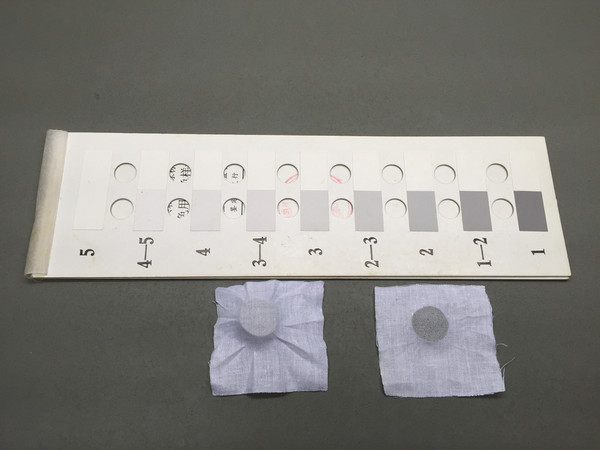

The color fastness grade is an indicator for evaluating the color fastness of fabrics, usually expressed in numbers. The color fastness is graded from 1 to 5 or from 1 to 8, where 1 is the worst color fastness and 8 is the best color fastness. The higher the grade, the less likely the color of the fabric will fade under different conditions, thus giving it better durability and quality.

Different color fastness testing methods can be used to test different types of color fastness. The following are several common color fastness testing methods:

(1) Color fastness water resistance test (ISO 105 E01)

This test method is used to measure the color fastness to water of fabrics. In the test, a standardized sample of fabric is exposed to water for a certain period of time, and the degree of color change in the fabric is assessed. Test results are usually expressed in numbers, with higher numbers indicating less color fading and better color fastness to water.

(2) Color fastness to perspiration test (ISO 105 E04)

This test method is used to measure the colorfastness of fabrics to perspiration. In the test, a standardized sample of fabric is exposed to a sweat solution containing salt and acid for a certain period of time, and the degree of color change in the fabric is then assessed. Test results are usually expressed in numbers, with higher numbers indicating less color fading and better color fastness to perspiration.

(3) Color fastness rubbing test (ISO 105 X12)

This test method is used to measure the colorfastness of fabrics to rubbing or abrasion. In the test, a standardized sample of fabric is exposed to a rubbing head and then subjected to multiple rubs or abrasions. Then, a standardized evaluation method is used to measure the color fastness, and according to the test results, the color fastness to rubbing grade of the fabric is evaluated.

(4) Color fastness to washing test (ISO 105 C06)

This test method is used to measure the color fastness of fabrics to laundering. In the test, a standardized sample of fabric is exposed to a washing machine and then subjected to multiple washes. Then, a standardized evaluation method is used to measure the color fastness, and based on the test results, the fabric's color fastness to washing level is evaluated.

(5) Color fastness to light test (ISO 105 B02)

This test method is used to measure the color fastness of fabrics to sunlight. In the test, a standardized sample of fabric is exposed to sunlight for a certain period of time, and the degree of color change in the fabric is assessed. Test results are usually expressed in numbers, with higher numbers indicating less color fading and better color fastness to light.

Color Fastness Testing Application

The ISO method of color fastness is widely used and involves many industries and products, such as clothing, home textiles, automotive interiors, medical supplies, etc. Test results can be used to evaluate and compare the quality and performance of different products, and help consumers choose products that are more durable and have better color fastness. In addition, color fastness testing can also be used in product design and development to ensure the performance and quality requirements of products under different conditions of use.

In conclusion, the color fastness ISO method is an important standardized method for evaluating the color fastness of fabrics, and can be used to test the color fastness of fabrics under different conditions, including water resistance, sweat resistance, friction resistance, washing resistance, light resistance, etc. This approach can help manufacturers, consumers and regulators assess the quality and performance of fabrics and ensure the durability of color and appearance of products during use.

Previous: Which component is measured by zipper test and sit and reach?

N e x t : what fabrics are exempt from flammability testing?