Search keywords:

product name, product type, model number,

test method, manufacturer, technique, application

Si 3000 Weather Ometer

BACKStandards:

AATCC TM16,AATCC TM16E,AATCC TM169,ASTM C1442,ASTM C1501,ASTM D904,ASTM D3424,ASTM D3451,ASTM D4101,ASTM D4303,ASTM D4355,ASTM D4459,ASTM D4798,ASTM D5010,ASTM D5071,ASTM D5794,ASTM D6083,ASTM D6551,ASTM D6577,ASTM D6662,ASTM D6695,ASTM G151,ASTM G155,GME 60292,ISO 105-B02,ISO 105-B04,ISO105-B06,ISO 11341,ISO3917,ISO4892-1,ISO 4892-2,ISO12040,JASO M346,M&S C9 C9A,PSA D27 1389 1431,GB/T 8427/14576

Applications:

It is widely used in plastics, paint coating, ink, packaging, automotive materials, photochemical materials, pigment dyes and textiles and other industries. The equipment has been certified by several international standards organizations. Si 3000 has gotten certification by multi international organization for standard.

Product Information:

Introduction

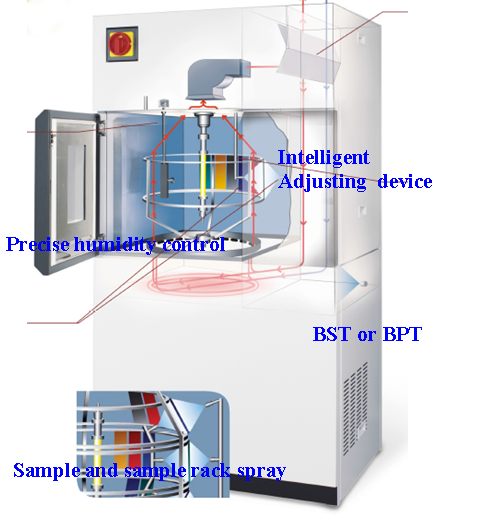

Si3000 Weather-Ometer and Fade-Ometer tester adopts water-cooled xenon lamp. It using argon arc lamp simulates natural climate ,solar and other experimental conditions to test the color and performance changing of dyes on textile. It can also test the material Anti-aging properties, can accurately test product life based on good reproducibility and reproducibility

Instructures

Instructures

◆ Xenon Lamp Cooling System- new Xenon lamp cooling system, better cooling effect and lower cooling water used.

◆ Rotating Sample Rack- Raise the exposure uniformity of each specimen.

◆ Control system - Enhanced control system can handle complex custom programs and simple preprogrammed test, simple operation interface and icon is clear and easy to understand ; Irradiation, temperature and humidity are programmable changing step by step, meet various test requirements by user.

◆ Intelligent and friendly operating system - intuitive LCD touch interface, comprehensive function, Multi languages can be selected; water purity indicator can monitor the input water quality; Smart Light Monitor ensures that the lamp is installed correctly.

◆ Irradiance closed-loop monitoring and automatic adjustment, can be calibrated by the irradiance calibration device on a regular basis. Radiation calibration device should get certificate from CNAS / A2LA / JAB or other international mutual recognition organization which should be certified by ISO 17025.

◆ Control system - Enhanced control system can handle complex custom programs and simple preprogrammed test, simple operation interface and icon is clear and easy to understand ; Irradiation, temperature and humidity are programmable changing step by step, meet various test requirements by user.

◆ Intelligent and friendly operating system - intuitive LCD touch interface, comprehensive function, Multi languages can be selected; water purity indicator can monitor the input water quality; Smart Light Monitor ensures that the lamp is installed correctly.

◆ Irradiance closed-loop monitoring and automatic adjustment, can be calibrated by the irradiance calibration device on a regular basis. Radiation calibration device should get certificate from CNAS / A2LA / JAB or other international mutual recognition organization which should be certified by ISO 17025.

Features

◆ Wetting (dark + spray) and dry (light + not spray) alternate program control function, automatic control of the chamber humidity, with back spray function. Spray pressure and flow is controllable and uniform.

◆ The control panel real-time displays the relevant settings and test parameters . When the program running parameters are overproof, the instrument has an alarm (stop) function.

◆ The machine preset the common used test standard when out of factory. It can restore the factory settings, and can customize and store more than 10 custom test program.

◆ Meet the test criteria: GB/T 1865-2009(JIS K5600-7-7-2008)、GB/T 16422.2-1999、GB/T 32088-2015、SAE J2527、SAE J2412-2004 etc.

◆ Equipped pure water system (including deionized water machine, pump, storage tank) which should meet the equipment operation requirements and spray water quality requirements

◆ With serial port or network communication function, the test parameters can be stored and exported.

Technical Parameters

| Items | Parameters |

| Light source | 4500 W water-cooled xenon arc lamp |

| Xenon lamp life | More than 1000 hours. The spectral energy distribution curve was stable after 300 hours |

| Filter | Internal and external filters (daylight filter, window glass filter, UV extension filter) can be replaceable |

| Irradiance control | 340/420 or 300-400nm select single point automatic control, optional second point monitoring |

| Lighting monitoring | Intelligent light monitoring |

| Relative humidity control | Automatic |

| Humidity range | Drying cycle Humidity: 20-80 ± 5% RH, wetting cycle Humidity: 95 ± 5% |

| Temperature control | Automatic Test chamber temperature control: 20-65 ± 2 ℃ |

| Temperature | Black Standard Temperature (BST) :50~100±2℃ Black Panel Temperature (BPT) :45~90±2℃ |

| Simultaneous control BPT or BST and chamber temperature | Standard |

| BPT/BST double control | Optional |

| Specimen frame type | Monolayer |

| Exposure test area | 2188cm2(339in2) |

| Power supply | 400/230V, 3phase, 4 wire, 50Hz, 38 A |

| HVAC-MJ/h (BTU/h) (maximum) | 26.06MJ/h (24703BTU/h, 275CFM) |

| Compressed air | 0.11m3/min (Max 4CFM), @552kPa, (80psi) |

| Water flow | Pressure: 38-345kPa (20-50psi) |

| Humidification: deionized water 0.12l / min | |

| Sample spray: deionized water 0.07l / min | |

| Sample rack spray: deionized water 0.07l / min | |

| Dimension | (L x W x H):95cm x 84cm x 183cm |

| Base | 115cm x 240cm |

| Weight | 404kg (890lb) |

| Daylight filter and UV extension filter @ 340 setting range | ≥0.51W/m |

| Window glass filter @ 420nm setting range | ≥1.1W/m |

| Irradiance control deviation | ±0.01W/m2 |

| @Tuv (300nm-400nm) between the average irradiance | More than 120W / m2 The irradiance E at any point on the surface of the specimen does not exceed ± 10% of the average of the irradiance on the entire surface. |

| Radiation exposure area | ≥3000cm2 Also accommodate specimen number ≥50 |

| Specimen size | Between 50*100mm and 70*150mm |

| Test area height (flat) | ≥30cm |

| Single automatic cycle test time setting upper limit | ≥2000 hours |